Introduction: Why Wool Processing Matters More Than Ever

Wool fabric has been utilized for millennia; however, the modern evolution of textile technology has greatly altered the way this natural fiber is perceived in the contemporary market. As consumers seek out easy-care, long-lasting, and environmentally friendly fabrics, traditional wool alone is no longer sufficient to meet all the demands. This is the place where Superwash wool, and specifically Carbonized Wool Superwash, is of increasing importance.

Understanding the distinction between standard wool and superwash wool is crucial to textile manufacturers, apparel brands, fabric consumers, and businesses that are focused on sustainability. Beyond the ability to shrink, the distinction is based on the treatment of fibers, their consistency of performance, manufacturing feasibility, and user experience.

This article provides a comprehensive, technical, and commercial comparison of wool and superwash wool that focuses on Carbonized Wool Superwash, a superior material that is commonly utilized in high-end knitwear, sports equipment, baby clothing, and industrial textiles.

What Is Wool? A Technical Overview

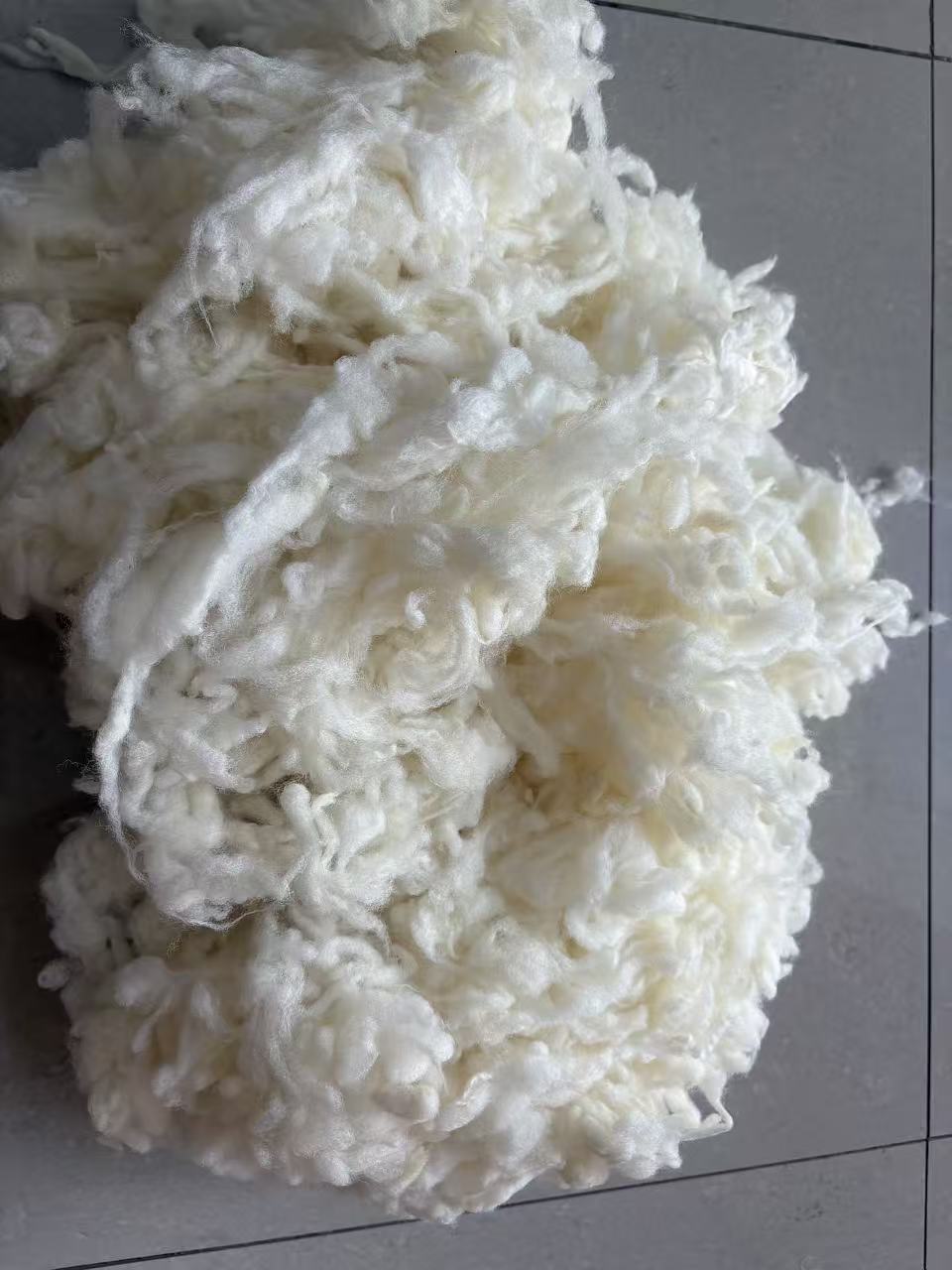

-

Definition of Wool Fiber

Wool is a natural fiber derived primarily from sheep, although similar fibers are also found in goats, alpacas, and other animals. Its primary component is keratin, the same protein that is found in human hair and nails.

What differentiates wool from other natural fibers is its structural composition. Every fiber of wool is surrounded by microscopic projections that overhang the surface. These projections:

Create a natural elasticity.

Insulation-quality air conditioning

Allow the felting to occur and the shrinking of the material to occur when exposed to heat, moisture, and movement.

-

The distinguishing properties of conventional wool are listed below

Untreated wool has several well-known benefits.

Excellent control of the thermal balance

Absorption of water vapor without having to feel it.

Ability to withstand natural odors

The capacity to resist fire

However, traditional wool has a deficiency:

Facing felting and compaction

Requiere de la limpieza de las manos o del secado.

Agitated by the mechanical process

Variations in hygienic quality caused by vegetable debris and impurities

These obstacles are precisely why superwash and carbonization methods were invented.

What Is Superwash Wool?

-

Definition of Superwash Wool

Superwash wool is wool that has been subjected to a specialized procedure that is intended to reduce or eliminate felting and shrinkage during the washing process with a machine.

The process of superwashing typically involves:

The surface of the fiber’s scales is altered.

Whether or not to smooth, remove, or cover the scales.

Increasing the fiber’s stability in heat and motion

As such, superwash wool is now machine washable, which increases its popularity in the commercial realm.

-

Why the Superwash Method was created

From a commercial perspective, untreated wool has problems:

High yields due to compaction

Disparate compatibility with automatic washes

More complex care documentation

Superwash wool addresses these concerns by creating a woolish:

More simple to maintain

More accessible to consumers

More appropriate for general wear

What Is Carbonised Wool Superwash?

-

Understanding the process of carbonization in the processing of wool

Carbonisation is a chemical purification process used to remove vegetable matter (VM) such as:

Burrs

Seeds

Small grass clippings

The procedure is typically initiated by:

Acid treatment to deconstruct cellulose-basedurities

Controlled burning of plant materials that are still present after the event.

Mechanical removal of carbonized material

This step is essential for obtaining high-quality wool that is suitable for fine needlework and high-end fabric.

-

Carbonized wool combined with a superwash treatment

Carbonized Wool Superwash has two advanced properties:

Carbonization to maintain neatness and consistency

Superwash treatment that improves the washability and stability of dimensions.

The outcome is a wool fiber that is:

exceptionally hygienic

Constant in quality

Advantage over competitors

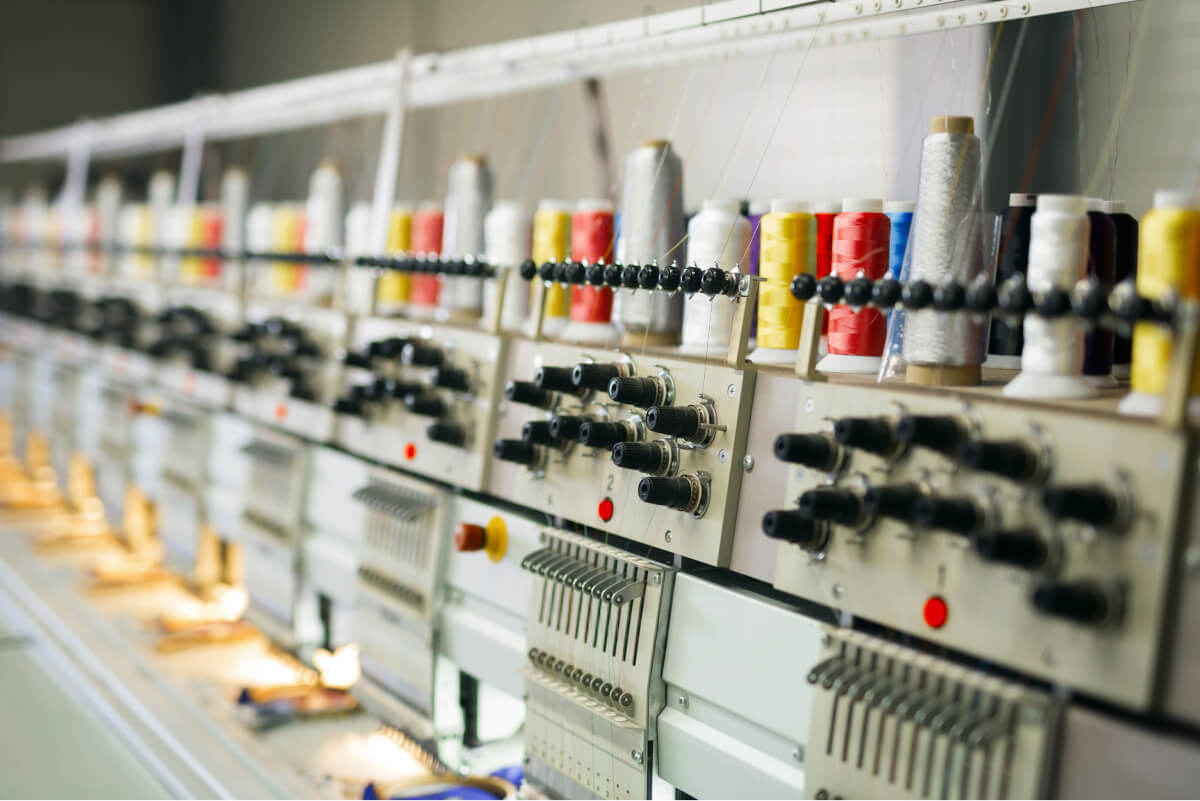

compatible with both industrially-funded knitting and weaving

This amalgamation is especially appreciated in export-driven textile chains.

Structural Differences: Wool vs Superwash Wool

-

Fiber surface topography

The greatest difference is located in the fiber’s surface:

- Conventional wool:

Overlapping scales that are prominent

High abrasion between the fibers

Easy access to the felting area.

- Superwash wool:

Scales are augmented with new features or layers of material.

Reduced between-fiber friction

Minimal scratching during cleaning

In Carbonized Wool Superwash, the fiber’s surface is both more hygienic and more consistent, which improves the downstream processing of the fiber.

-

Impact on the formation of Yarn

Because of the decreased friction:

Superwash wool fibers are more consistently produced.

The frequency of yarn breakage is lower.

More intricate patterns are possible

This causes the production of Carbonized Wool Superwash to be appropriate for:

Heavierweight bales

Small gauge sweaters

Combined fabric systems

Performance Differences in Real-World Use

-

Washability and Dimensional Stability

This is the most obvious difference:

| Property | Wool | Carbonised Wool Superwash |

| Machine wash | No | Yes |

| Shrinkage risk | High | Very low |

| Felting | Common | Minimal |

| Shape retention | Moderate | Excellent |

For brands targeting modern consumers, machine washability is no longer optional.

-

Softness and Skin Comfort

Carbonised Wool Superwash often feels:

Softer against the skin

Less itchy

More uniform in texture

This is due to:

Removal of coarse impurities

Smoother fiber surfaces

Reduced fiber ends protruding from yarn

Wool vs Superwash Wool: Application Differences by Industry

While both wool and superwash wool are derived from natural animal fibers, their processing methods lead to significant differences in performance, care, and potential for industry application. Understanding these discrepancies will assist manufacturers, brands, and consumers in selecting the appropriate material for each application.

-

Apparel & Fashion Industry

| Aspect | Wool | Superwash Wool |

| Typical Use | Coats, suits, scarves, sweaters | Knitwear, T-shirts, base layers |

| Washability | Hand wash or dry clean | Machine washable |

| Shrink Resistance | Low | High |

| Consumer Preference | Traditional & luxury | Modern & convenience-focused |

Industry Insight:

Fashion brands targeting mass markets or export markets prefer superwash wool due to easy care and consistent sizing.

-

Sportswear & Outdoor Apparel

| Aspect | Wool | Superwash Wool |

| Moisture Management | Excellent | Excellent |

| Durability Under Washing | Moderate | High |

| Comfort Against Skin | May feel coarse | Softer, smoother |

| Typical Products | Thermal layers, socks | Activewear, performance knitwear |

Industry Insight:

Superwash wool is widely used in outdoor, hiking, and performance apparel where frequent washing and durability are essential.

-

Baby & Children’s Products

| Aspect | Wool | Superwash Wool |

| Skin Sensitivity | Medium | High suitability |

| Care Requirements | High | Low |

| Safety & Comfort | Good | Excellent |

| Typical Products | Blankets, hats | Baby clothing, rompers |

Industry Insight:

Superwash wool dominates this segment due to softness, hygiene, and easy maintenance.

-

Home Textiles

| Aspect | Wool | Superwash Wool |

| Common Applications | Carpets, throws, blankets | Bedding, washable covers |

| Maintenance | Dry clean preferred | Machine washable |

| Dimensional Stability | Moderate | High |

| Longevity | High | Very high |

Industry Insight:

Traditional wool is still popular for carpets and rugs, while superwash wool is favored for washable home textiles.

-

Industrial & Technical Textiles

| Aspect | Wool | Superwash Wool |

| Fiber Cleanliness | Moderate | High (carbonised & treated) |

| Process Stability | Medium | High |

| Consistency | Variable | Uniform |

| Typical Use | Insulation, felts | Filtration, precision textiles |

Industry Insight:

Carbonised superwash wool is preferred where fiber purity, consistency, and process control are critical.

-

Luxury & Handcrafted Products

| Aspect | Wool | Superwash Wool |

| Aesthetic Authenticity | Very high | Moderate |

| Traditional Value | Strong | Moderate |

| Care Expectation | Accepted | Less accepted |

| Typical Products | Handwoven textiles, artisanal garments | Limited use |

Industry Insight:

Luxury and artisan brands often favor untreated wool for authenticity and heritage value.

Structural Differences: Wool vs Superwash Wool

Despite the fact that wool and superwash wool are derived from the same chemical composition, their internal and external structures are markedly different as a result of post-processing treatments. These structural alterations directly affect performance, consistency, and ultimate utilization.

-

Fiber surface structure

Wool:

Natural wool’s fibers are characterized by a variety of intersecting scales. These scales are interlocked by heat, moisture, and movement, which causes felting and shrinking.

Superwash:

The process of superwashing alters or smoothes the surface scales; it can either take away part of the scales or cover them with a coating, which diminishes the amount of interlocking between the scales.

Structural Impact:

Decreased felting propensity and enhanced stability in superwash wool.

-

Fiber diameter and uniformity

Wool:

The diameter of fibers may be naturally variable within a batch, which will lead to slight inconsistencies in the texture and appearance.

Superwash:

The processing procedure promotes uniformity and smoothness in the fibers, which results in more consistent fabric and yarn structures.

Structural Impact:

Better consistency of fabric pattern and consistent behavior of knitting or weaving.

-

Fiber Core Integrity

Wool:

Maintains its original cortex composition, which contributes to stretchiness, wrinkles, and thermal insulation.

Superwash:

The core fiber composition is primarily unchanged, but the surface treatments can have a slight effect on the flexibility of the material, depending on the degree of processing.

Structural Impact:

The concept of elastic recovery is still prominent in both, and the superwash wool continues to have a more focused performance.

-

Interaction between fibers

Wool:

High fiber-to-felix ratio due to the surface scales increases the cohesion of the fibers, but it also increases the likelihood of felting.

Superwash:

Lower fiber-to-fiber friction due to flat or coated surfaces.

Structural Impact:

Easy processing of the yarn, smooth fabric, and decreased pilling.

-

Spatial Stability

Wool:

Adversely affected by structural malformations during washing or drying.

Superwash:

Engineered to maintain the alignment of fibers and the dimensions of fabric in repeated washes.

Structural Impact:

Constant fabric design over time.

-

Moisture Interaction at the Fiber Level

Wool:

Hygroscopic by nature, with a high moisture content in the fiber.

Superwash:

Maintains the moisture-absorbing core while surface treatments slightly alter the behavior of releasing moisture.

Structural Impact:

Effective moisture management with increased surface porosity.

-

Fabric’s surface topography

Wool:

Fabric’s surfaces are more complex and organic.

Superwash:

Fabrics appear more smooth, cleaner, and more consistent at the microscopic level.

Structural Impact:

Augmented aesthetics and enhanced comfort for adjacent skin applications.

How to Choose Between Wool and Carbonised Wool Superwash?

When choosing wool fabric for apparel, home décor, or business use, understanding the distinction between common and carbonized wool is crucial. Each option has its own advantages that are specific to the requirements of performance, the intended result, and the maintenance that is expected.

-

Know the Primary Difference

Wool:

Animal fibers are renowned for their warmth, breathability, moisture control, and comfort. Traditional wool may have been contaminated with vegetable materials and typically needs to be washed carefully.

Carbonized wool superwash:

Wool that has been carbonized to eliminate vegetable content, then undergoes a superwash treatment to enhance the washability, stability, and smoothness of the surface.

-

Think about the quality and hygienic nature of the fabric

Wool:

May have residual burrs, seeds, or plant material depending on the level of processing.

Carbonized wool superwash:

Carbonization purges nearly all of the vegetable’s impurities, which results in more uniform, higher-quality fibers, ideal for superior textiles.

Use carbonized wool’s superwash if the fiber’s cleanliness and consistency are of paramount importance.

-

Assess the capacity to be washed and maintained

Wool:

Usually requires cleaning with a hand or dry method. Susceptible to felting and shrinking if machine-washed.

Carbonized wool superwash:

Hand-washable, resistant to shrinkage, and more fácil to maintain.

Select carbonized wool superwash for clothing or other materials that need to be washed frequently or with limited maintenance.

-

Contrast the Shrinkage and the Stability of Dimensions

Wool:

The natural scale structure causes the felting and size changes associated with heat and movement.

Carbonized wool superwash:

The superwash treatment smooths the fibers, which offers a great degree of dimensional consistency.

For consistent measurement and long-term shape retention, carbonized wool superwash is superior to cotton fabric.

-

Evaluate the practical applications that result from the end of a product’s life cycle

Wool is appropriate for:

Traditional sockwear

Coats and scarves

Handicrafted textiles and blankets

Carbonized wool is great for:

High-end knitwear

Outdoor and activewear apparel

Baby gear

Garments that can be machine-washed.

Industrial and technological textiles

-

Performance and Comfor

Both substances offer:

Naturally occurring warmth

Breathability

Moisture control

However, carbonized wool typically has:

More delicate sensation

Less severe skin reactions

More even coloring

-

Cost and value analysis

Wool:

Lower costs associated with processing, suitable for traditional or homemade products.

Carbonized wool superwash:

Higher-pricing but more durable, convenient, and user-friendly.

Select based on whether the performance and ease of care are greater than the initial cost of the material.

Conclusion: Wool vs Superwash Wool — A Clear Industry Shift

The distinction between wool and superwash wool is more extensive than simply the capacity to be washed. At the manufacturing level, it demonstrates a shift towards efficiency, consistency, and scale.

Carbonized wool superwash intersects at the by:

- Natural fiber history

- Elaborate textile design

- Modern consumer desires

For consumers, manufacturers, and buyers who seek a dependable, washable, and high-quality wool solution, Carbonized Wool Superwash is now a mainstream option.