ملخص المقال : ملخص المقال :

Determining the best type of wool requires more than comparing softness or price; it demands an understanding of fiber structure, micron count, durability, thermal regulation, and end-use performance.

Textiles: Fiber to fabric by Bernard P. Corbman and Wool: Science and Technology edited by W. S. Simpson, different types of wool fibers have different mechanical, thermal, and aesthetic properties depending on the breed, processing, and design of the fabric.

This article focuses on the most popular types of wool that are used in fabric design, integrating scientific knowledge of textile production, apparel manufacturing standards, and practical applications in real-world industries.

Introduction: Why “Best Wool” Is a Misleading but Important Question

The query “what is the best type of wool?” is frequently searched on topics related to textiles and apparel. However, from a professional perspective on textiles, the concept of a singular “optimal” wool is inherently incorrect. Wool is not a singular material that is characterized by a specific composition; instead, it is a large category of natural protein fibers that have a variety of different diameters, crimps, elasticity, surface structures, and processing behavior.

For consumers, manufacturers, and designers, the actual concern is not which wool is best suited to all applications, but rather which fabric type of wool performs the best in a specific context. A نسيج صوفي that is suitable for high-end fashion may be completely ineffective for carpets or outdoors, and vice versa.

This article discusses the issue from the perspective of an industry dedicated to wool fabric; it explains the different types of wool in terms of their measurable, functional attributes rather than their subjectively described attributes alone.

Understanding Wool Fabric at the Fiber Level

To accurately assess the different types of wool, it is crucial to understand how they are produced at the fiber level.

- Fiber diameter and the number of microns in the fiber’s composition

One of the most important factors in the evaluation of wool is the fiber diameter, which is commonly measured in microns. Finer fibers are more easily bendable, which results in a softer fabric, while coarser fibers have a higher resilience and resistance to abrasion.

Fine wool: under 19 micrometers

Medium-sized wool: 19-24 microns

Fine wool: between 8 and 24 microns

The number of microns affects the comfort, drape, and practicality of the wool fabric’s final use.

- Crimp and Elastic Recovery

Wool fibers have a natural crimp, which contributes to the characteristic flexibility and resilience of wool fabric. Higher levels of crimp have a positive effect on the recovery of wrinkles and insulation; this is particularly beneficial to wool fabric that is intended for clothing.

- Moisture Absorption and Breathability

Unlike other synthetic fibers, wool is capable of absorbing up to 30% of its weight in moisture without becoming wet. This hygroscopic behavior facilitates the regulation of body temperature, one of the primary reasons why wool has been popular across climates.

Merino Wool: The Benchmark for Fine Wool Fabric

Merino wool is commonly considered the highest quality of wool fabric, and it is particularly popular in the apparel industry.

- The Reason Why Merino wool is cherished so highly

Merino sheep have exceptionally thin fibers, which are often between 15 and 19 microns. This fineness causes the wool fabric to be soft against the skin and have a limited number of prickles.

- Use of Merino wool fabric

Luxury clothing and accessories

High-end fashion

Base layers of performance

Heavierweight scarves and shawls

Merino’s wool fabric has an exceptional combination of softness, breathability, and thermal regulation; it is therefore one of the most popular options in the market.

- Limitations

Despite its benefits, Merino wool is less effective at combating abrasion than other wool types that are coarser, and it typically has a higher cost.

Cashmere and Specialty Wools: Luxury Within the Wool Fabric Category

Despite not being technically sheep’s wool, fibers like cashmere, alpaca, and vicuña are frequently associated with wool fabric.

- Cashmere

Cashmere fibers are extremely delicate and soft, but they lack the stability and elasticity of wool fibers in their traditional form. Cashmere fabric is exorbitant, but it is prone to pilling.

- Alpaca’s wool fabric

Alpaca’s fibers are smoother and lack the surface scales found in sheep’s wool, which results in a lower tendency to felt and a distinct drape.

- Why They Don’t Always Have to Be “Better.”

From a fabric designer’s perspective, these fibers are often combined with wool to enhance longevity and stretchiness.

Crossbred Wool: Strength and Practicality in Wool Fabric

Crossbred sheep have medium to large-sized fibers that are typically between 24 and 35 microns.

Performance Traits

High tensile strength

Superior abrasion capacity

Lower price

superior toughness

Common Purpose

Outsidewear fabric

Upholstery fabric made of wool

Cushions and floozies

Crossbred fabric that is wool-based is exceptional in fabric applications that require longevity and resilience over the softness of the fabric.

Coarse Wool: Industrial and Heavy-Duty Wool Fabric

Coax types of wool that are over 35 micrometers are uncommon in clothing, but they have a significant role in technical and industrial endeavors.

Common Examples

Carpets

Insulation components

Felts and cushions

These wool fabrics focus on the structural integrity and wear resistance of the fabric over its comfort.

Comparative Overview of Common Wool Types

| Wool Type | Average Micron | Softness | Durability | Common Wool Fabric Uses |

| Merino Wool | 15–19 | عالية جداً | متوسط | Apparel, knitwear |

| Crossbred Wool | 24–30 | متوسط | عالية | Coats, upholstery |

| Coarse Wool | 35+ | منخفضة | عالية جداً | Carpets, felts |

| Alpaca | 18–25 | عالية | متوسط | Outerwear, blends |

| Cashmere | 14–16 | Extremely high | منخفضة | Luxury knitwear |

Processing Methods That Affect Wool Fabric Quality

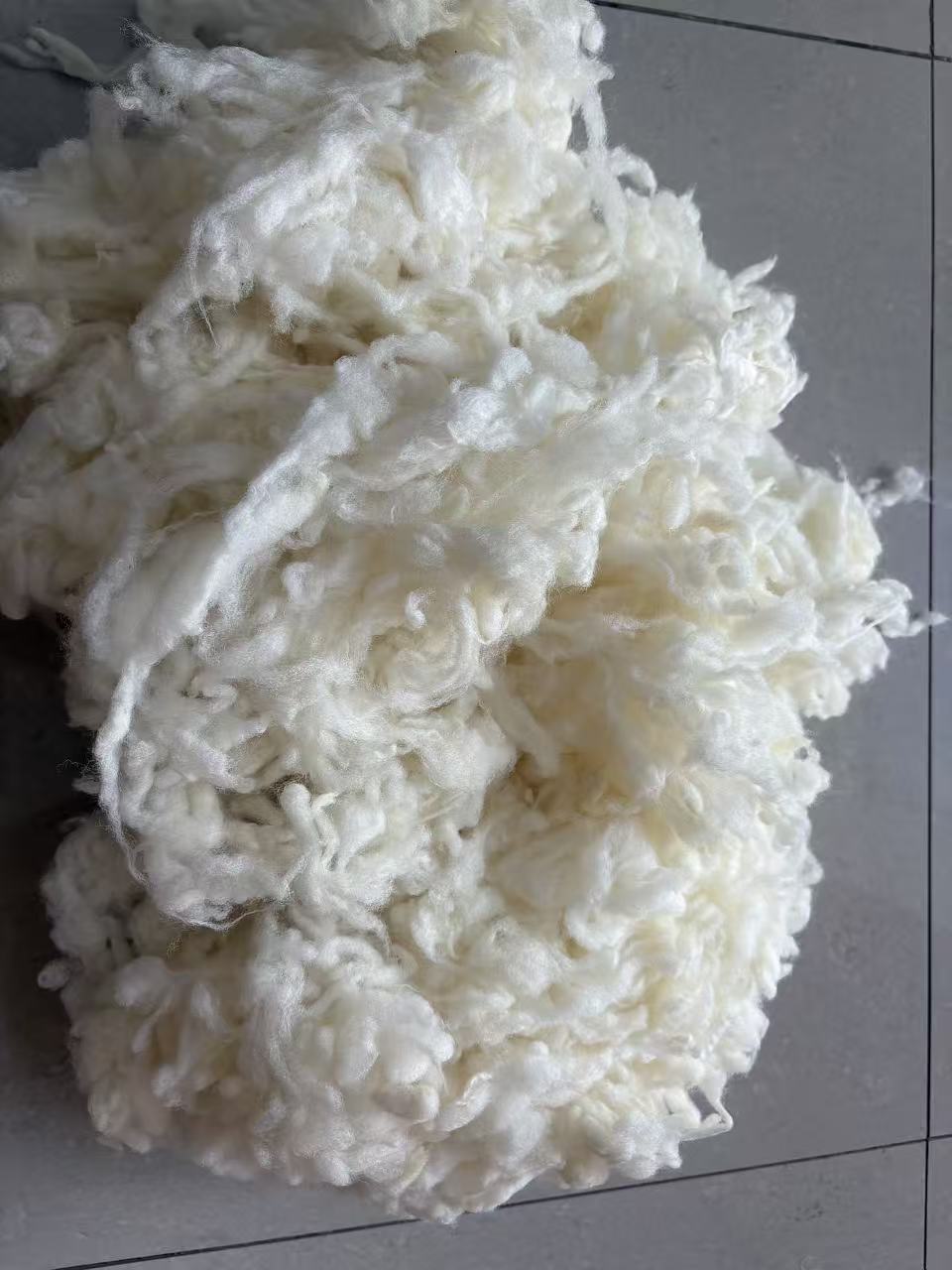

The procedure of processing wool from its raw state to a finished product has a significant impact on the feel, strength, and longevity of the fabric.

- Fiber Optic Cable Selecting and Organizing

Finer fibers (measured in microns) result in softer fabric.

Increasing the length of the staple increases the strength of the yarn and the duration of the fabric.

Careful selection decreases variability and errors.

- Scrapping and cleaning

Remove grease (lanos), dirt, and other impurities.

Over-scouring can detrimentally affect the fibers, while under-scouring has a negative effect on the coloring and quality of the end product.

- The difference between carding andCombing

Carded wool: more refined, warmer, and more pleasant coloring.

Combed wool (worsted method): more powerful, more refined, and more consistent surface.

- Yarn and Spinning

The degree of twisting has an effect on the strength, stretchiness, and resistance to pilling.

Lower tension = softer sensation؛ higher tension = more durable

- The End of the Game

Fulling (felting) increases volume and temperature.

anti-shrink (superwash) treatments enhance the washability of clothing, but have an effect on the long term sustainability of the garments.

Surface brushing increases the softness of the material, but it may diminish the resistance to abrasion.

Blended Wool Fabrics: Optimizing Performance

Combining wool with other fibers enables manufacturers to improve the performance and cost of their products.

Common Wool Combination and Advantages

Wool +polyester

Increased durability and resistance to wrinkles

Lower expense and simpler care

Less breathable than pure wool.

Wool +ylon

Increased resistance to abrading

Perfect for socks, coats, and upholstery.

Wool + Silk

softer and more delicate sensation

High-end apparel uses

Wool + Cotton or Viscose

Increased air circulation

Warmth and softness for temperate climates

Key principle:

Blending should promote the end goal, while not negatively impacting the core benefits of wool.

Sustainability and Ethical Considerations in Wool Fabric Selection

Wool is a fiber that is renewable and biodegradable, but its sustainability is dependent on the responsible procurement and treatment of its fibers.

- Animal Welfare

Look for certifications that discuss the ethical practice of shearing and farming.

Accountable wool regulations promote animal safety and provide traceability.

- الأثر البيئي

Wool is made from a biodegradable material and lacks microplastics.

Conventional sheep farming is resource-intensive if not well-managed.

Effective water conservation and efficient pasture management have a negative environmental impact.

- Concerns regarding chemicals

Dyeing and anti-shrink treatments can have environmental consequences.

A preference for low-density fabrics and reduced chemical treatment increases the sustainability of the fabric.

- The longevity of a product as a sustainability factor

The long lifespan of wool reduces the frequency of replacement.

Garments that are durable have an offset towards higher initial environmental and cost expenditures.

How to Choose the Best Wool Fabric for Your Application?

Selecting the appropriate wool fabric is dependent on having a strong grasp of the material’s properties that fit the functional requirements.

Key selection criteria

- End Use

Fashion apparel (formalwear, knitwear, and outerwear)

Home textiles ( quilts, upholstery)

Industrial or performance-based applications

- Fiber Density ( Micron Count )

≤20-25 microns: superior clothing, next-to-skin relaxation

19–24 microns: common clothing, suits.

25-45 microns: Overskirts, upholstery

- fabric construction

Woven fabric vs. Knitted fabric

Worsted and woolen fabric.

- Care Necessities

Machine-washable versus dry cleaning only

Increase resistance to shrinkage and maintain stability in dimensions

- Sustainability Objectives

Verified procurement

Combine the ingredients

The longevity of fabric and its recyclability.

FAQ: Wool Fabric and Wool Types

Q1: What is the softest fabric type?

Merino wool and cashmere are both considered to be extremely soft, with cashmere providing superior longevity.

Q2: Is the wool of Merino animals more beneficial than the regular kind?

For clothing that involves apparel or skin, Merino fabric typically has better performance.

Q3: What fabric is the longest-lasting?

Crude and crossbred wool fabric has a superior lifespan.

Q4: Is the wool fabric appropriate for clothing in the summer?

Yes. Fine Merino fibers have effective temperature regulation, even in temperate climates.

Q5: Does fabric made of wool shrink easily?

Shrinkage is influenced by the processing and finalizing; properly treated wool fabrics have a tendency to resist shrinkage well.

Conclusion: What Is the Best Type of Wool?

From a professional and scientific perspective, the best type of wool is dependent on the intended purpose of the wool fabric. Merino’s wool is characterized by its softness and comfort, crossbred wool is superior in its durability, and coarse wool is essential to the industrial sector. When considered through the fiber science and fabric engineering disciplines rather than as a marketing plank, wool becomes apparent as one of the most versatile and eagerly devoured textile materials on the planet.

For everyone involved, understanding the properties of wool is crucial to finding the best wool. Not necessarily in theory, but in practice.