In the world of wool fabric and apparel, fiber processing and final technology significantly affect the performance, durability, feel, and value of the product. Two significant methods that are often discussed in separate passages are the carbonizing process and the superwash treatment. Combining them results in a fabric or yarn that can be called “carbonized wool superwash“; this fabric or yarn possesses attributes derived from both processes, including increased purity, reduced vegetable content (via carbonization), and machine-washable properties that are shrink-resistant or felty.

For those involved in textile manufacturing, apparel design, and fabric purchasing, understanding what Carbonized Wool Superwash has to offer is crucial when selecting wool for superior clothing, knittedwear, tailored products, or blended goods. This article investigates:

- The procedures and definitions of carbonized and superwash wool.

- What the combination means

- Benefits and drawbacks of Carbonized Superwash

- Typical uses, considerations of quality, and appropriateness

- How to assess and procure with confidence

- Industry updates and consumer guidance

What Is Carbonised Wool and What Is Superwash Wool — Definitions & Processing

To understand the “Carbonized Wool Superwash,” you must understand its two fundamental processes.

-

Carbonized wool: description and purpose

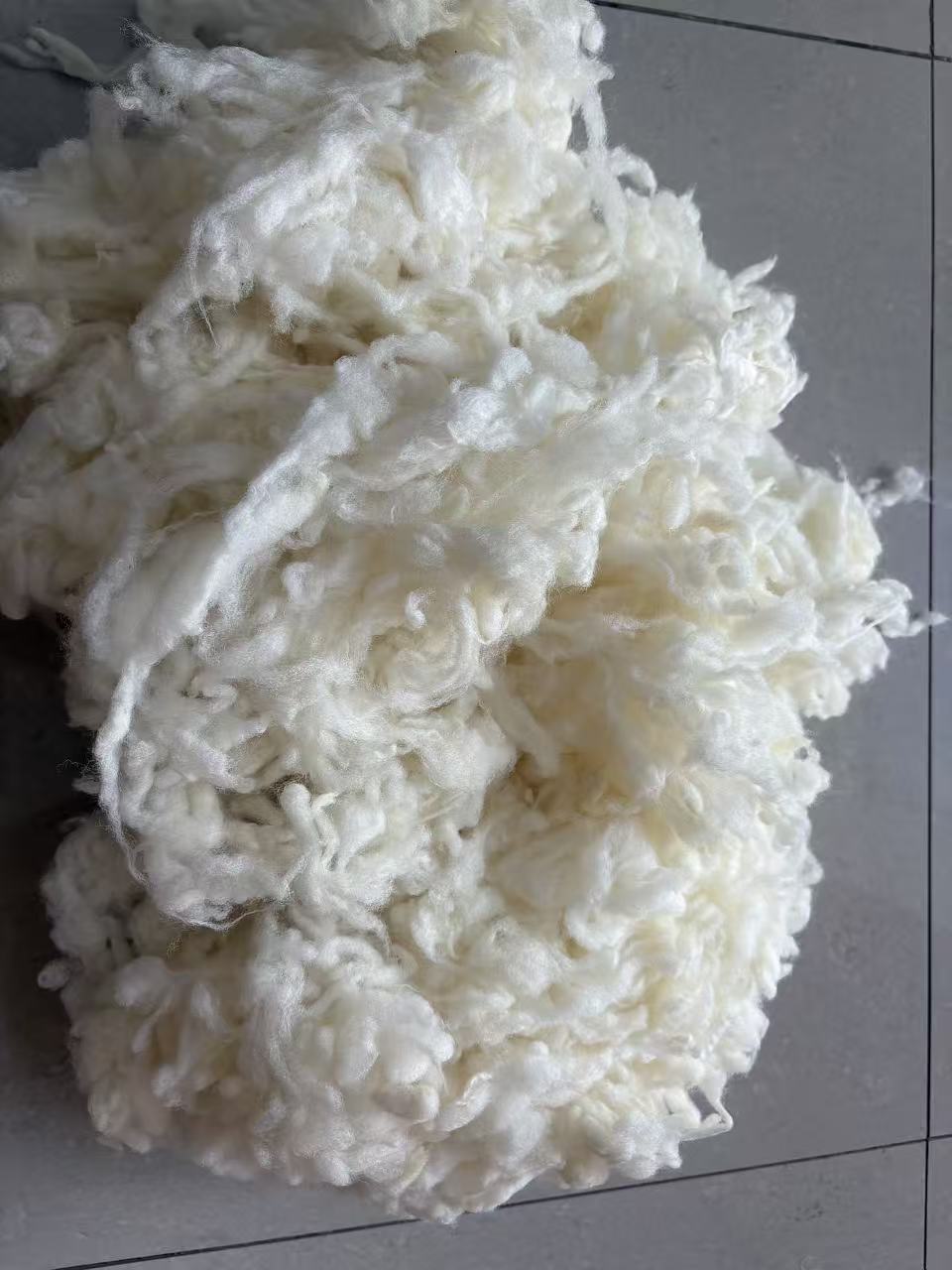

Carbonized wool is wool that has been subjected to a chemical process that purges the majority of the vegetable content from within the fleece following shearing. In wool that is raw or has been scoured, these components can still be present following the washing process, which will lead to fabric issues, irritation, or a decreased degree of comfort. Carbonization enhances the hygienic and sterile nature of wool’s fibers.

Common process of carbonization (standard industry):

The wool’s fleece is cleaned and scrubbed in order to eliminate lanolin, sweat, oils, and surface debris.

After it is subjected to a controlled acid bath that decomposes organic material that is not wool (such as cellulose or lignin), the bath is still considered a part of the treatment process. However, the fiber is primarily composed of keratin, which is not affected by the process.

After treatment with acid, the wool is converted to a state that allows it to remain strong; it’s then washed, dried, and de-acidified to maintain the fiber’s strength.

The outcome: a more refined, softer, and more consistent fiber that is minimally affected by vegetable matter. This is ideal for producing fine worsted or knitted yarns, smooth fabric, and comfortable clothing.

The beneficial effects of carbonized wool are numerous:

Decreased “prickle factor” — fewer burrs or plant residues that cause skin irritation.

Cleaner design – ideal for delicate fabrics, worsted, knitted, and upholstered.

Increased dye retention and uniformity are achieved – these are now contaminants that do not take up dye or cause uneven color.

Higher quality is more important for garments that require softness, comfort, or superior finishing.

Because of these benefits, carbonized wool is often sought after for high-end knitwear, worsted clothing, baby gear (which is more concerned with softness), and other superior wool products.

-

Superwash wool: description and purpose

Superwash wool is wool that has been treated with a finishing substance that makes it machine-washable and resistant to shrinkage. Typically, untreated wool will feel or shrink when heated, stirred, or subject to moisture; this makes it unsuitable for everyday cleaning. The superwash method guarantees stability, ease of care, and a user-friendly approach to maintaining the product.

Common methods of producing superwash wool include:

Chemical treatment: utilizing chlorine-based or similar methods to eliminate or smooth the outer fiber layers of wool, then covering or stroking to prevent the layers from interlocking (which results in felting).

Polymer coating: after the scale is excised, the fiber is covered with a thin, malleable polymer layer that provides shelter.

Enzyme therapy: mulesing or specialized chemical treatments that smooth the fiber’s surface, followed by careful washing. This is less common, but more environmentally responsible.

Superwash wool is characterized by a lack of special precautions when it is washed in the home (e.g., with cold or warm water, a gentle cycle), the material is retained in its shape and size, and it is avoided in the contemporary fashion and knitwear market.

-

Combining Carbonized with Superwash — What is meant by the term “Carbonized Wool Superwash”?

By combining the carbonizing process and a superwash treatment, wool producers hope to produce a high-quality, skin-friendly, and easy-to-care-for fabric or yarn that retains the natural comfort of wool but averts two significant drawbacks: the contamination of vegetable matter and the risk of shrinkage or felting during washing. The entire process, if executed correctly, produces fibers that are:

Freed from the constriction of plant stems, this improves the softness and wear comfort.

Clean and consistent – enhancing the uniformity of colors and the quality of fabric.

Machine-washable and shrinking or felting resistant — increasing the usability and ease for consumers.

For brands that sell apparel and consumers, such as wool represents a cost-effective, versatile material that is ideal for garments that require softness, comfort, low maintenance, and consistent quality across manufacturing runs.

Why Carbonised Wool Superwash Matters — Advantages for Industry & Consumers

Understanding the combined benefits promotes the value of Carbonized Wool Superwash and identifies the situations where it is truly beneficial.

-

Increased Comfort and Ease of Wear

Carbonized wool’s superwash garments are more comfortable to the skin and have a low risk of irritation. The lack of burrs or residual fibers from fleece increases the comfort of the user, particularly pertinent to underwear, baby clothes, next-to-skin knittedwear, and garments intended for sensitive-skin consumers.

Additionally, because fiber debris is removed, the fabric’s surface is smoother and consistent, which improves the comfort, quality of vision, and overall appeal of the garment.

-

Ease of Care and Practicality

One of the traditional barriers to entry in wool is the complexity of care; many consumers avoid wearing wool garments because of the fear of shrinking or felting during the laundering process. Superwash treatment addresses this concern: Carbonized wool Superwash clothing can be machine-washed (typically on a gentle or wool cycle), which represents a significant advantage to modern, consumer-oriented brands and ready-to-wear stores.

This ease of care extends the range of applications of wool to include everyday wear, travel, knitwear, casual tops, and blends.

-

Constant Quality and the Dyeing or finishing of the fabric.

Because the vegetable content (burrs, dirt) is removed, the uniformity of the dye uptake is increased; any remaining impurities that might impede the dye’s absorption or cause defects are minimized. This results in a higher yield, less waste, and more consistent final product quality—which is of value to the manufacturer.

Additionally, increased fiber quality and consistency have a positive effect on the fabric’s hand, decreasing the number of fabric defects and increasing the perceived quality of the product, all of which are beneficial for high-end apparel and textile products.

-

The market value, differentiation, and general popularity of the product.

Brands can promote Carbonized Wool Superwash clothing as being of high quality, soft, and easy to care for, combining the benefits of traditional wool (warmth, breathability, and natural fiber) with the modern convenience of washing, softening, and comfort. This attracts not only traditional wool enthusiasts, but also a larger audience: young consumers, travelers, urban residents, and environmentally conscious consumers who want a simple lifestyle without sacrifice to the natural fibers.

Additionally, in export markets that have different laundering conditions or consumer preferences, easy-care woolwear can increase the competitiveness of wool in comparison to synthetic fibers or blended fabrics.

-

Product flexibility in a Blended Product

Because Carbonized Wool Superwash fibers are hygienic, stable, and consistent, they are well-suited for blends (e.g., wool + cotton, wool + synthetic fibers) – this will allow designers to create garments that have both the thermal and comfort benefits of wool plus durability, stretch, cost-efficiency, or easy care. This flexibility increases the variety of products available in the knitwear, suits, casualwear, and technical areas.

Typical Applications & Suitable Products for Carbonised Wool Superwash

Taking into account the benefits and limitations, Carbonized Wool Superwash is particularly beneficial for the following product types.

-

Everyday Knitwear and Pre-worn Wool Clothes

Sweaters, cardigans, and pullovers: Easy to care for wool clothing that can be machine-washed, these garments offer a comfortable feel without requiring high maintenance.

Casual tops, hoodies, and long-sleeved shirts: These items are intended for consumers who want a wool feel but want to do so in a convenient manner.

Blended knitwear (wool + cotton, wool + synthetic): Soft, simple to care for blended fabric that takes advantage of the wool’s warmth and breathability while enhancing durability and decreasing cost.

-

Children and Baby Clothing/ Products

Because Carbonized Wool Superwash diminishes the need for needlework and ensures softness, it’s particularly beneficial for:

Baby’s clothing, blankets for the baby.

children’s sweaters or comfortable clothing

wool children’s hats, gloves, boots.

Machine-washable wool benefits parents by reducing the hassle of laundry, one of the most significant benefits.

-

Travel and Easy-Care Wear collections

Travelers, commuters, or regular wear that is wool-based benefits from being washable and having low maintenance. Travelackets, wool-based trousers, knitted scarves, lightweight sweaters, all of these become more common with the Carbonized Wool Superwash.

-

Blended fabric and mid-range wool products

For markets that value accessibility and ease of care, e.g., fast fashion, mid-range knitwear, and export clothing-carbonized wool superwash is a balance of function, ease, and cost. Combined products (e.g., the combination of wool with acrylic or polyester can be exploited to take advantage of the processed wool while still maintaining a manageable cost.

-

Upholstery, Home textiles, and Accessories for wool

Softness, hygienic properties, and simple washes make Carbonized Wool Superwash appropriate for:

Provide warmth, comfort, and security, all with the bonus of being beautiful and unique.

wool vests, hats, gloves, shawls – where the ease of care is paramount

Home textile products are concerned with the value of wool’s intrinsic properties (warmth, softness), but they may need to be frequently cleaned.

What to Check When Sourcing Carbonised Wool Superwash — Buyer’s Quality Checklist

Because variability between suppliers can be substantial, when sourcing Wool Superwash Carbonised materials, buyers, mills, and brands should evaluate:

| ✅ What to check | 🔍 Why it’s important |

| Source of fleece and wool grade (fiber diameter, cleanliness, staple length) | High-quality wool ensures softness, durability, dyeability, and even after processing. |

| Carbonising process details (acid concentration, neutralization, washing quality, residue testing) | To avoid fiber damage or residual chemical presence, ensuring fiber strength and safety. |

| Superwash treatment method (chlorine-based vs polymer coating vs enzyme-based) | Influences fiber feel, durability, shrink resistance, wash performance, and environmental impact |

| Post-treatment fiber strength testing (tensile strength, shrink test, color fastness, pilling/recovery) | Ensures that fiber properties remain acceptable after processing / finishing |

| Batch-to-batch consistency and mill traceability | Avoids quality variation between lots — critical for brand consistency |

| Dye uptake and finishing performance (color uniformity, wash cycles, shrinkage) | Guarantees finished garment quality and consumer satisfaction |

| Compatibility with blending yarns or knit/weave processes | Some finishing may affect blending or spinning — need to test before bulk ordering |

| Environmental compliance / chemical residue / eco-labeling (if required) | For brands emphasizing sustainability or targeting sensitive markets |

| Cost vs. performance analysis (overhead processing cost vs final product pricing and market positioning) | To ensure the product remains competitive while delivering added value |

Only through rigorous evaluation and testing can buyers ensure they receive genuine, high-quality Carbonised Wool Superwash fiber or fabric — avoiding disappointment or rejection due to poor finishing.

Challenges & Common Misconceptions About Carbonised Wool Superwash

Despite the obvious benefits, there are still some misconceptions or problems in the industry. Understanding them promotes a better approach to sourcing and design.

❗ Inaccuracy: “All Superwash Wool Is the Same.”

Reality: the superwash method is variable. Some people employ harsh chlorine treatments and polymer coating that can adversely affect the fiber’s hand, durability, or environmental acceptance, while others utilize more lenient, environmentally friendly enzyme processes that have different results. Assuming that all suppliers have the same quality leads to inconsistent products as a final result.

Falsehood: “Carbonizing Does Not Imply a Loss of Shear Force”

While carbonizing is intended to eliminate plant material, it must be cautiously executed. Over-exposure to acid, not fully neutralized acid, or insufficient washing may adversely affect the fiber keratin in the clothing, reduce the tensile strength of the clothing, and shorten the garment’s lifespan. Without effective quality oversight, carbonized wool may lack performance.

❗ Inaccuracy: the description of the product as being without shrinkage, without pilling, and unable to be maintained.

Even superwash wool may become smaller or wrinkled under harsh conditions of washing ( high heat, aggressive detergents), or it may lose its shape if you handle it incorrectly. Buyers and consumers should still follow the recommended care instructions (gentle cycle, cold water, mild detergent, avoid heat drying) for the long run.

❗ Opposition: A Soft Power and Its Impact on the World’s Future

The final treatments (such as scale removal or coating) may adversely affect the fiber’s surface, which may lead to a decrease in the wool’s natural resilience, stretchiness, or thermal performance. For some purposes (heavy outerwear, high-end garments), treated wool may not have the same performance as untreated wool or wool-based fabric.

❗ Opposition: Environmental Pressure and Regulation on Chemical Endings

Chlorine-based pre-wash treatments and acidic carbonization create wastewater and chemical compounds—in areas with stringent environmental regulations, this negatively affects the manufacturing process, increases costs, or prohibits certain procedures. Increasing demand for environmentally friendly wool processing prompted mills to seek alternative methods (enzyme-based, biodegradable coatings), but these methods may be more costly or less common.

Given the obstacles, successful utilization of Carbonized Wool Superwash is dependent on informed choice, precise oversight, documented processes, and realistic expectations.

Buyer’s Guide: When and Why to Choose Carbonised Wool Superwash (vs Regular Wool or Synthetic Alternatives)

For consumers of textile, apparel brands, or managers of sourcing, here is a practical explanation of when to consider Carbonized Wool Superwash and when to abandon it.

✅ Choose Carbonised Wool Superwash If:

You create apparel that is both wrinkled and ready to wear that is intended for everyday use (sweaters, cardigans, tops) that is targeted by consumers who like to have easy access to it.

Comfort and softness are considered paramount ( next to the skin, baby clothes, casual clothing).

You want to sell wool with the capacity to be machine-washed and have a low maintenance regimen. This will expand the wool’s reach to additional markets that have a lower maintenance standard than classic wool garments.

You want to combine wool with other fibers and want to have consistently pure, uncontaminated fibers of wool.

You reach markets that have small laundering facilities, which makes it easier to care for wool without treating it.

You want to market your products via a premium feel, plus ease of care.

Reconsider if:

You craft beautiful, functional outerwear, or you create high-end thermalwear that is unprocessed or minimally treated. The wool may have better thermal performance, durability, and traditional properties.

The cost of the product is high, and the target consumer is price-sensitive; as a result, the premium associated with the processing may not be justified.

Your market has a focus on “chemical-free, natural” textile claims. These claims may conflict with the brand’s message.

Environmental regulations or certifications necessitate low-chemical or environmentally friendly processing. In this instance, make sure your wool processing adheres to standards or seeks alternative, environmentally friendly treatments.

Ultimately, carbonized wool superwash is beneficial when comfort, ease, and practicality are important, but it may not be appropriate for every type of wool or brand’s position.

Summary & Strategic Takeaways for Industry Stakeholders

To synthesize the discussion:

Carbonized Wool Superwash is not a new concept; it combines two already established methods of wool processing (carbonizing + superwashing) in order to address the common barriers to the adoption of wool (vegetable matter, maintenance, felting).

It’s considered a strategic product category that blends the superior qualities of wool with the modern conveniences of consumers. This category widens the scope of use of wool across casual wear, knitwear, blends, and mass-market apparel.

For mills and suppliers, implementing this process correctly requires stringent quality control, skilled processing, environmental compliance, and consistency, but when done properly, it produces high-value fiber or fabric that can be exported or used in high-end domestic markets.

For brands and consumers, Carbonized Wool Superwash offers a distinct market advantage, a larger audience, and a value-added product position that is especially important in regards to care instructions, product labeling, and marketing.

However, there are trade-offs: increased expense, some potential loss of wool’s natural properties (such as oil, the thermal behavior of chemicals, and environmental impact), all of which lead to a decision not to utilize them in heavy-duty, historical, or environmentally conscious lines.

Future projects that utilize sustainability as a driving force in the finishing of textiles, the wool-blend innovation that is simple to implement, and the demand for natural fibers that are easy to care for suggest that Carbonized Wool Superwash will have a significant role in the global textile and apparel industries over the next decade.

Conclusion

In a fabric world that is more convenient, comfortable, and versatile as it defines the consumer’s choice, Carbonized Wool Superwash is a striking matchup that combines the benefits of wool’s timeless comfort and the natural beauty of its fibers, while minimizing the negative aspects of traditional methods (itchiness, maintenance, and felting). For those who want to invest in quality processing and transparent sourcing, it represents an opportunity to expand the wool’s market reach beyond the specialized realm of knitwear to include everyday items in the wardrobe.

If you’re considering wool fabric for your next design or are evaluating new sources of supply, Carbonized Wool Superwash should be taken into consideration, but be treated with the same degree of technical rigor as any other form of fabrication: demand documentation, test samples, verify protocols for finishing, and ensure consistency of supply chain.

With considered sourcing and a clear understanding, Carbonized Wool Superwash can become a link between traditional wool craftsmanship and the demands of modern clothing consumers – combining heritage, comfort, and practicality in one fiber.