Riassunto dell'articolo: il nostro lavoro

Tessuto di lana has been one of the most important natural textiles in human history, valued for its warmth, breathability, durability, and sustainability.

According to The Wool Handbook (Woodhead Publishing) and the Textile Institute’s Fabric Science reference, wool is not only known by a single name but is represented by a wide family of fabric types, such as worsted wool, merino wool, tweed, flannel, felt, and gabardine, each defined by fiber quality, spinning method, and fabric structure.

This article provides a complete, industry-level explanation of what another name for wool fabric is, why so many alternative names exist, how they differ technically, and how professionals select the right wool fabric for apparel, home textiles, and industrial applications.

Introduction: Why Wool Fabric Has So Many Names

When people ask “What is another name for wool fabric?”, they are often surprised to learn that wool is not a single material but an entire category of fabrics. In professional textile manufacturing, “wool fabric” is an umbrella term covering dozens of fabric types, each with distinct performance characteristics.

These different names exist because wool fabrics vary by:

- Fiber source (Merino, Shetland, Alpaca, Cashmere, etc.)

- Yarn type (woolen vs worsted)

- Fabric construction (woven, knitted, felted)

- End-use performance requirements

Understanding these names is critical for apparel brands, fabric buyers, and textile engineers who must balance comfort, durability, cost, and sustainability.

What Is Wool Fabric? A Technical Definition

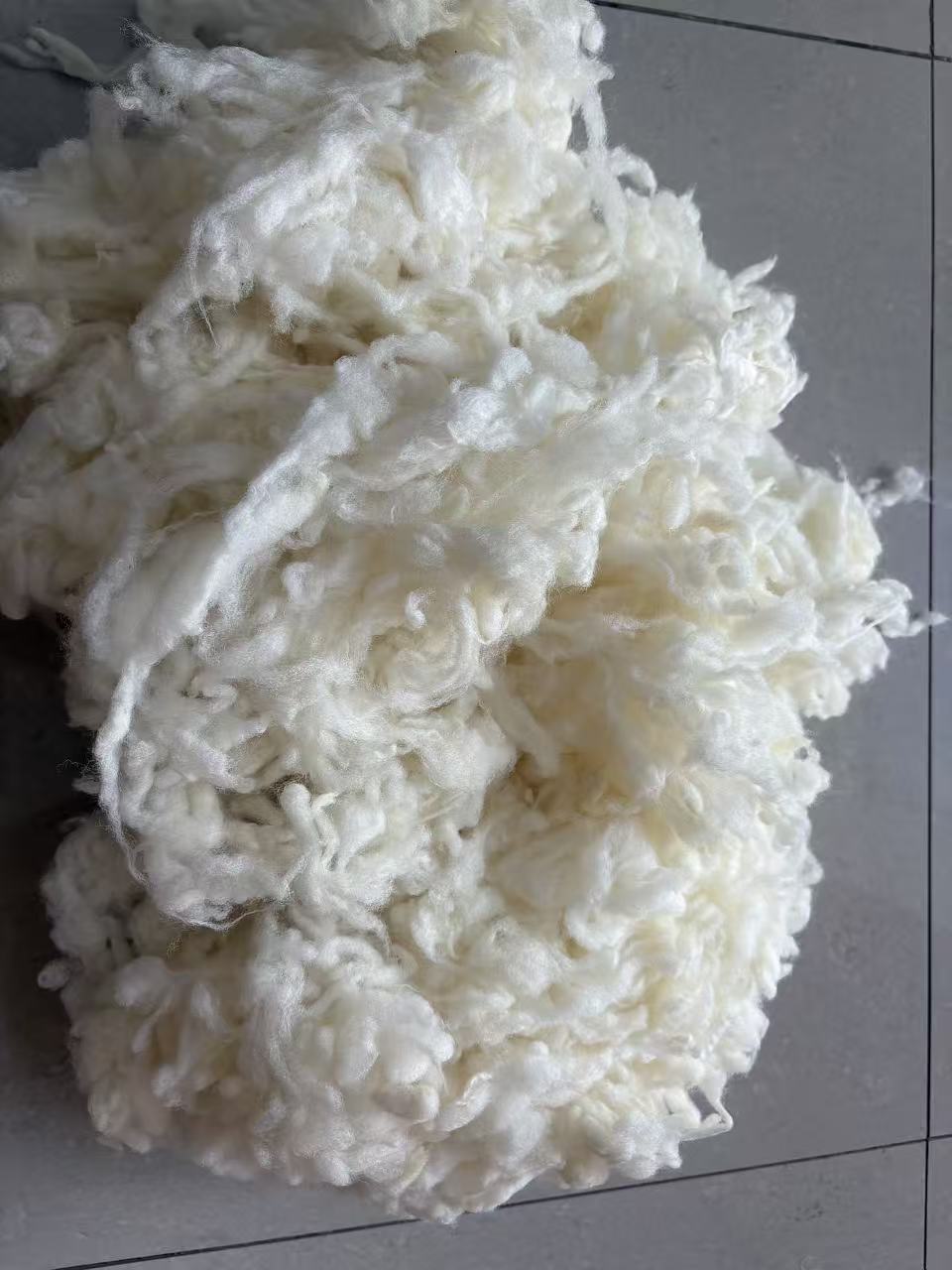

Wool fabric is a textile made from animal hair fibers, most commonly sheep, that is cleaned, carded, spun into yarn, and then woven or knitted into cloth.

According to the Textile Institute, wool is defined as:

“A natural protein fiber composed primarily of keratin, characterized by crimp, elasticity, and hygroscopic behavior.”

This structure explains why wool fabric offers:

- Thermal insulation

- Moisture management

- Natural elasticity

- Flame resistance

- Odor control

Another Name for Wool Fabric: The Most Common Alternatives

Below is a professional overview of the most widely recognized alternative names for wool fabric

-

Tessuto in lana pettinata

Worsted wool is one of the most important “other names” for wool fabric in the apparel industry.

Made from long, fine fibers

Combed to align fibers parallel

Produces smooth, strong, and lightweight fabrics

Used for:

Men’s suits, tailoring, corporate uniforms, luxury outerwear

-

Woolen Fabric

Woolen fabric is the traditional counterpart to worsted wool.

Fibre più corte

Carded rather than combed

Softer, bulkier, and warmer

Used for:

Coats, blankets, scarves, knitwear

-

Merino Wool Fabric

Merino wool is named after the Merino sheep and is known for exceptional fineness.

Fiber diameter: 15–24 microns

Soft against skin

Excellent temperature regulation

Used for:

Base layers, activewear, luxury sweaters, baby clothing

-

Tweed Fabric

Tweed is a coarse wool fabric traditionally associated with British heritage.

Heavyweight, textured weave

Highly durable

Excellent insulation

Used for:

Jackets, coats, countryside fashion, upholstery

-

Flannel Wool Fabric

Flannel is a brushed wool fabric with a soft surface.

Raised nap for warmth

Comfortable and breathable

Used for:

Shirts, pajamas, winter trousers, bedding

-

Felt Wool Fabric

Felt is a non-woven wool fabric made by matting fibers together.

No weaving or knitting

Highly insulating

Excellent sound and heat absorption

Used for:

Industrial insulation, craft, footwear, acoustic panels

-

Gabardine Wool Fabric

Gabardine is a tightly woven wool fabric with a steep twill structure.

Smooth face

High durability

Wrinkle resistance

Used for:

Suits, uniforms, trench coats

-

Cashmere and Alpaca (Luxury Wool Fabrics)

These are premium “wool fabrics” from special animal fibers.

| Fabric Name | Fiber Source | Key Characteristics | Usi tipici |

| Cashmere | Cashmere goat | Ultra-soft, lightweight, warm | Luxury scarves, sweaters |

| Alpaca | Alpaca camelid | Strong, warm, hypoallergenic | Coats, blankets, knitwear |

| Mohair | Angora goat | Lustrous, durable | Fashion coats, upholstery |

Why Wool Fabric Has So Many Different Names?

The diversity of names exists because the textile industry classifies wool fabric by fiber quality, yarn system, and fabric structure.

Fiber Level Naming

- Merino wool

- Lambswool

- Shetland wool

- Cashmere

- Alpaca

Yarn Level Naming

- Worsted yarn

- Woolen yarn

Fabric Level Naming

- Tweed

- Flannel

- Felt

- Gabardine

- Melton

- Herringbone

Each name reflects how the fabric performs in real-world use.

Performance Comparison of Common Wool Fabrics

| Wool Fabric Name | Calore | Softness | Durability | Typical Application |

| Worsted Wool | Medio | Alto | Alto | Suits, tailoring |

| Woolen Fabric | Alto | Medio | Medio | Coats, blankets |

| Merino Wool | Medio | Very High | Medio | Activewear, base layers |

| Tweed | Alto | Medio | Very High | Jackets, upholstery |

| Flannel | Medio | Alto | Medio | Shirts, sleepwear |

| Felt | Very High | Basso | Alto | Industrial insulation |

Industry Applications of Wool Fabric

- Fashion and Apparel

Wool fabric is central to:

- Business suits

- Knitwear

- Outerwear

- Performance clothing

- Tessili per la casa

- Blankets

- Upholstery

- Curtains

- Carpets

- Industrial and Technical Uses

- Thermal insulation

- Acoustic panels

- Fire-resistant clothing

- Filtration fabrics

Why Wool Fabric Outperforms Many Synthetic Fabrics?

In a world dominated by synthetic textiles, wool fabric continues to stand out as a high-performance, sustainable, and naturally intelligent fiber. From outdoor apparel to technical uniforms and luxury knitwear, wool consistently outperforms many synthetic fabrics across comfort, durability, and environmental impact.

- Superior Thermal Regulation

Wool fibers actively regulate body temperature:

- Keeps you warm in cold conditions

- Stays cool in hot environments

- Adapts automatically to climate changes

This makes wool ideal for all-season performance, unlike synthetics that trap heat or feel cold when damp.

- Natural Moisture Management

Wool absorbs up to 35% of its weight in moisture without feeling wet, then releases it through evaporation.

| Proprietà | Lana | Synthetic Fabrics |

| Moisture Absorption | Alto | Basso |

| Dry Comfort | Eccellente | Poor when saturated |

| Odor Control | Natural | Chemical treatments required |

- Odor Resistance Without Chemicals

Wool naturally inhibits odor-causing bacteria, reducing the need for:

- Antimicrobial chemical finishes

- Frequent washing

- Deodorizing treatments

This extends garment life and lowers environmental impact.

- Sustainability Advantage

| Factor | Tessuto di lana | Synthetic Fabric |

| Raw Material | Renewable (sheep) | Fossil fuel-based |

| Biodegradable | Sì | No |

| Microplastics | None | Major pollution source |

| Lifecycle Impact | Basso | Alto |

- Fire and Safety Performance

Wool is naturally flame-resistant:

- Self-extinguishing

- Does not melt or drip

- Low smoke toxicity

This makes wool ideal for protective clothing and safety applications.

- Long-Term Durability

Wool fibers bend over 20,000 times without breaking, offering:

- Excellent resilience

- Wrinkle recovery

- Long garment service life

- Comfort and Skin Health

Soft and breathable

Hypoallergenic for most users

Gentle on sensitive skin

Modern fine-gauge merino wool eliminates the traditional “itchy” perception.

Sustainability and the Future of Wool Fabric

Wool is one of the oldest textile fibers in human history, yet it is increasingly recognized as a future-ready, sustainable material. As the global textile industry moves toward low-impact, circular, and responsible production, wool fabric stands out for its renewability, durability, and natural performance.

- Wool as a Naturally Sustainable Fiber

Renewable and Biodegradable

Wool is 100% renewable, shorn annually from sheep

It is biodegradable, decomposing naturally without microplastic pollution

Wool fibers return nutrients to the soil at the end of life

Low Microplastic Impact

Unlike synthetic fibers, wool does not release persistent microplastics during washing, making it environmentally safer for waterways and marine life.

- Environmental Benefits Across the Lifecycle

| Lifecycle Stage | Sustainability Advantage |

| Raw Material | Renewable animal fiber |

| Manufacturing | Lower energy needs vs synthetic polymers |

| Use Phase | Odor resistance reduces washing frequency |

| End of Life | Fully biodegradable and recyclable |

- Advances in Responsible Wool Production

Animal Welfare Standards

Responsible Wool Standard (RWS)

ZQ Merino and equivalent programs

Emphasis on humane treatment and land stewardship

Reduced Environmental Footprint

Improved pasture management

Lower methane emissions through feed innovation

Water-efficient scouring and dyeing processes

- Innovation in Wool Processing and Performance

Modern technology is redefining wool’s role in future textiles:

Superwash treatments with lower environmental impact

Fine-gauge merino wool for lightweight and next-to-skin comfort

Wool blends for enhanced durability and stretch

Carbonized wool for industrial and technical applications

These innovations extend wool’s use beyond fashion into performance, medical, and technical textiles.

- Wool in a Circular Economy

Longevity and Reusability

Wool garments last longer, resisting odor, wrinkles, and wear, reducing the need for frequent replacement.

Recycling and Upcycling

Mechanical recycling into insulation or yarn blends

Growing interest in chemical recycling technologies

Second-life applications in home and industrial products

- Wool vs Synthetic Fabrics: A Sustainability Perspective

| Aspetto | Tessuto di lana | Synthetic Fabric |

| Raw Material | Renewable | Fossil-based |

| Biodegradability | Alto | Basso |

| Microplastic Pollution | None | Significant |

| Odor Resistance | Natural | Chemical-treated |

| Longevità | Alto | Moderato |

- Consumer Demand and Market Trends

Rising demand for natural, traceable materials

Growth of eco-labels and sustainability certifications

Preference for quality over fast fashion

Increased adoption in outdoor, activewear, and wellness sectors

- Challenges and the Road Ahead

Key Challenges

Cost competitiveness vs synthetics

Climate impact of livestock farming

Need for scalable recycling systems

Future Direction

Climate-smart wool farming

Bio-based and low-impact processing

Transparent supply chains

Hybrid wool fabrics combining performance and sustainability

FAQ: Wool Fabric and Its Other Names

- What is another name for wool fabric?

Common alternative names include worsted wool, woolen fabric, Merino wool, tweed, flannel, and felt, depending on fiber quality and construction.

- Is Merino the same as wool fabric?

Merino is a type of wool fabric made from fine Merino sheep fibers, offering superior softness and comfort.

- What is the difference between worsted wool and woolen fabric?

Worsted wool is smooth and strong, while woolen fabric is softer, bulkier, and warmer due to shorter fibers and carded spinning.

- Is cashmere considered a wool fabric?

Yes. Cashmere is a luxury wool fabric made from the undercoat of cashmere goats.

- Why does wool fabric cost more than polyester?

Because wool requires animal farming, careful fiber grading, and complex processing, but it offers superior comfort, durability, and sustainability.

Conclusion: Understanding Another Name for Wool Fabric

So, what is another name for wool fabric?

The answer is not just one name but an entire family of professional textile terms: worsted wool, woolen fabric, Merino wool, tweed, flannel, felt, gabardine, cashmere, and alpaca.

Each name represents a specific performance profile shaped by fiber quality, spinning technology, and fabric construction. For fashion brands, textile buyers, and product developers, understanding these distinctions is essential to selecting the right wool fabric for comfort, durability, sustainability, and market positioning.

By integrating authoritative textile literature, industry performance data, and real-world applications, this guide provides a complete, Google-optimized explanation that supports informed decision-making across the global textile supply chain.