Введение: Обзор карбонизированной шерсти Superwash

Шерсть традиционно считалась высоко ценимым натуральным волокном благодаря своим разнообразным свойствам, включая тепло, долговечность и универсальность. Со временем достижения в области текстильной обработки привели к созданию превосходных изделий из шерсти, в том числе карбонизированной шерсти, которая в результате стала особенно популярной. Эта специализированная шерсть обладает преимуществами карбонизации - процедуры, очищающей сырую шерсть от примесей и других материалов, а также эффектом супермойки, благодаря которому шерсть можно стирать в машинке, она устойчива к усадке и более проста в уходе.

Создание Суперстирка карбонизированной шерсти напрямую зависит от требований современных потребителей и производителей. Натуральная шерсть обеспечивает расслабление, гибкость и терморегуляцию, однако ее обработка сопряжена с определенными трудностями: войлоком, усадкой и остаточными примесями, которые могут негативно повлиять на процесс и качество конечного продукта. Сочетая карбонизацию и супермойку, шерстяная промышленность разработала материал, который не только сохраняет естественные свойства волокон, но и способствует легкости обработки, равномерному окрашиванию и общей долговечности.

Карбонизированная шерсть играет важнейшую роль в производстве элитной моды, домашнего текстиля и технических тканей. Процесс карбонизации очищает волокно от заусенцев, семян и других примесей, что снижает частоту простоев и улучшает качество пряжи. И наоборот, метод супермойки позволяет волокну выдерживать многократные стирки без усадки и войлока. Этот метод продлевает срок службы одежды и повышает удобство для потребителя.

Помимо функциональных преимуществ, карбонизированная шерсть является значительным достижением в области экологической безопасности. Современные фабрики используют экологически безопасные и биоразлагаемые технологии карбонизации, чтобы снизить расход химикатов и уменьшить воздействие на окружающую среду при обработке супершерсти. Такой подход соответствует глобальной популярности устойчивых практик и повышения качества в текстильном производстве.

В конечном итоге сочетание карбонизации и суперпромывки позволяет получить шерстяное волокно, отвечающее требованиям практичности, производительности и роскоши. В результате этого процесса получается гладкий, прочный, устойчивый к окрашиванию и простой в уходе материал, который идеально подходит для изготовления одежды высокого класса, трикотажа и текстильных изделий с высокими эксплуатационными характеристиками. В следующих разделах мы обсудим технические аспекты карбонизации и супермойки, а также расскажем об основных преимуществах супермойки карбонизированной шерсти в мировой текстильной промышленности.

Понимание карбонизации шерсти

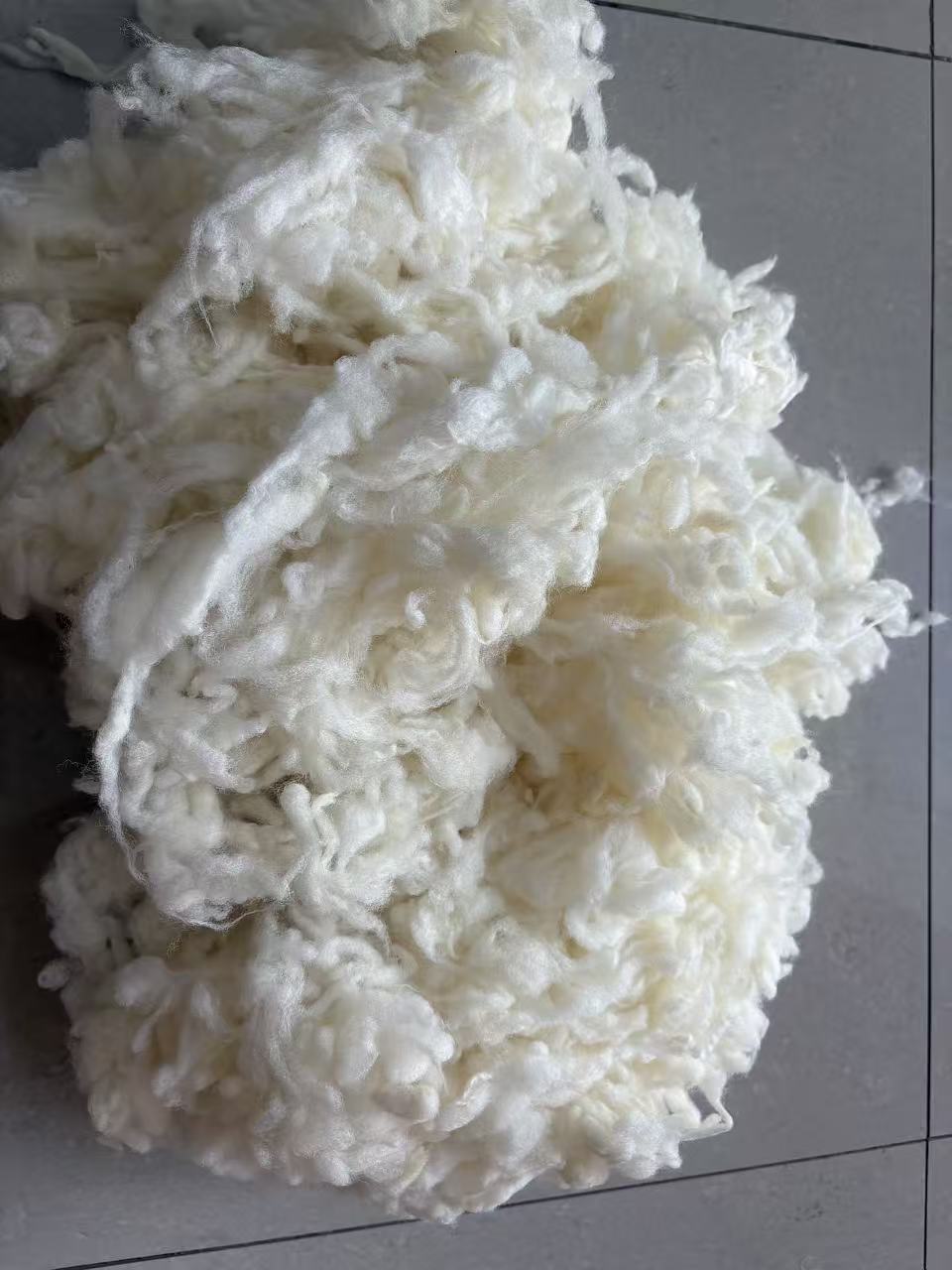

Качество и возможности шерсти в первую очередь зависят от ее первоначальной обработки. Одним из важнейших этапов создания карбонизированной шерсти является процесс карбонизации, в ходе которого шерсть очищается от растительных примесей, в результате чего получается более тонкое и однородное волокно, идеально подходящее для производства высококачественной ткани.

-

Что включает в себя карбонизация?

Карбонизация - это процедура, в ходе которой с помощью химических веществ и температуры удаляются такие примеси, как семена, стебли, ветки и другие органические остатки, которые обычно содержатся в сырой шерсти. Эти остатки естественным образом присутствуют на пастбищах во время выпаса овец и могут негативно повлиять на обработку волокон, ткачество и окрашивание, если их не обработать. Благодаря использованию контролируемой смеси кислот, которая обычно включает серную или муравьиную кислоту, карбонизация позволяет удалить нежелательный растительный материал, сохраняя при этом мягкость и целостность волокон шерсти.

Процедура обычно начинается с:

Подкисление: Шерсть погружается в особый кислотный раствор, который либо растворяет, либо ослабляет растительный состав.

Нейтрализация и сушка: После кислотного процесса шерсть полностью нейтрализуют и сушат, чтобы уплотнить волокна, что позволит в дальнейшем обрабатывать их, например, кардочесанием, прядением или супермойкой.

Точность имеет первостепенное значение в процессе карбонизации. Чрезмерное воздействие кислоты или слишком сильный нагрев могут негативно сказаться на волокнах; это может привести к снижению прочности на разрыв или потере хрупкости. Неправильная обработка приводит к остаточному загрязнению, что может вызвать неравномерность рисунка и проблемы с тканью. На современных фабриках используются автоматизированные системы, контролирующие концентрацию химических веществ, температуру и время выдержки. Это обеспечивает постоянное качество волокна и сокращает количество отходов.

-

Преимущества карбонизации

Процесс карбонизации имеет ряд существенных преимуществ:

Повышенная чистота волокна: удаление растительных волокон в процессе просеивания или шелушения обеспечивает получение более рафинированного, чистого волокна, что сокращает время, необходимое для работы станка в процессе прядения или ткачества.

Повышенное поглощение красителя: в шерсти примеси могут препятствовать равномерному поглощению цвета. Карбонизированные волокна дают равномерную, яркую окраску.

Повышение эффективности производства: Более чистые волокна шерсти легче проходят через машины, что снижает вероятность разрывов и других дефектов, увеличивает выход продукции и снижает затраты.

Основа метода супермойки: Равномерные, чистые волокна имеют решающее значение для эффективности метода супермойки; они обеспечивают гладкое покрытие и максимально возможную усадку.

-

Экологические соображения

Производство современного текстиля способствовало повышению экологической ответственности. Системы замкнутого цикла используют кислоты, которые уже есть в системе, сокращают количество используемой воды и сводят к минимуму выделение химикатов. Другие фабрики используют ферменты или биохимические методы обработки, чтобы смягчить растительную фракцию, сохраняя при этом качество волокна.

-

Резюме

Понимание процесса карбонизации имеет ключевое значение для понимания эффекта супермойки карбонизированной шерсти. Очищая от примесей и стандартизируя качество волокна, карбонизация создает основу для превосходной шерсти, обладающей прочностью, мягкостью и устойчивой окраской. Эта процедура гарантирует, что шерсть подготовлена к следующему шагу - достижению превосходных результатов в плане качества и долговечности для одежды и текстиля премиум-класса.

Технология суперстирки и ее значение

В то время как карбонизация заботится о чистоте волокна, технология супермойки использует уже готовые атрибуты шерсти, что делает ее подходящей для современных потребителей и бизнеса. Супермойка - это процедура, направленная на устранение войлока и уменьшение усадки, которые характерны для необработанной шерсти. Сочетая карбонизированные волокна с процессом супермойки, производители создают карбонизированную шерсть супермойки - материал, сочетающий в себе природные свойства шерсти с практичностью и долговечностью современного устройства.

-

Что означает шерсть Superwash?

Волокна натуральной шерсти покрыты мелкими чешуйками. При чистке или встряхивании эти чешуйки сцепляются между собой, что приводит к войлоку, усадке и деформации. При супермойке поверхность волокна увеличивается или покрывается шерстью, чтобы предотвратить сцепление чешуек; это позволяет шерсти пушиться без усадки.

Обычно для достижения эффекта супермытья используются следующие подходы:

Хлорирование: Мягкое хлорирование предполагает удаление или сглаживание чешуек, состоящих из волокон, что предотвращает войлокообразование. Этот метод применяется для минимизации воздействия на окружающую среду.

Полимерное покрытие: На волокна наносится тонкое полимерное покрытие, которое предотвращает образование войлока, обеспечивая при этом мягкость и воздухопроницаемость.

Энзимная обработка: Процессы на основе ферментов оказывают селективное воздействие на волокна более экологичным способом; они являются устойчивой альтернативой химическим процессам.

-

Преимущества технологии Superwash многочисленны.

Метод супермойки имеет ряд преимуществ, которые способствуют улучшению эксплуатационных характеристик шерсти и удовлетворению запросов потребителей.

Устойчивость к усадке: Позволяет избежать изменений размеров, которые происходят во время стирки и могут привести к потере размера или формы одежды.

Простота в уходе: Позволяет стирать без необходимости ручной стирки или химчистки, что соответствует современному образу жизни.

Долговечность волокон: Уменьшает износ и пиллинг, сохраняя мягкость и прочность при многократных стирках.

Улучшенное окрашивание и вывод: Гладкая поверхность и равномерное поглощение цвета, улучшающее эстетику ткани.

Расширенное применение: Позволяет использовать шерсть в трикотаже, верхней одежде, домашнем текстиле и спортивной одежде, где необходимость в стирке имеет первостепенное значение.

-

Комбинация с обугленной шерстью

При использовании карбонизированной шерсти метод супермойки повышает функциональность волокна, сохраняя его чистоту. Карбонизация способствует формированию гигиеничной, плоской основы, которая обеспечивает равномерное, чистое покрытие и превосходную усадку. Полученная в результате супермойки карбонизированная шерсть подходит для изготовления одежды высокого класса, технических тканей и других целей, требующих одновременно качества и практичности.

От такого слияния выигрывают и производители, и потребители. У фабрик меньше недостатков и более эффективная обработка, а потребители наслаждаются мягкой, прочной и простой в уходе одеждой. Альянс между карбонизацией и супермойкой является значимым в области технологии шерсти, сочетая традиции с современными целями производительности.

-

Экологические соображения

При разработке процессов супермойки также уделяется внимание экологичности. Хлорирование может привести к вредным побочным эффектам, но современные фабрики часто используют системы замкнутого цикла, которые нейтрализуются, биоразлагаемые покрытия или энзимы, которые уменьшают воздействие на окружающую среду. Сочетая эти методы с карбонизированной шерстью, производители могут выпускать высококачественный, экологически безопасный текстиль, который привлекает потребителей, осознающих последствия своей покупки.

Основные преимущества карбонизированной шерсти Superwash

Сочетание карбонизации и супермойки позволило получить шерстяной продукт, обладающий множеством преимуществ, как функциональных и эстетических, так и практических. Понимание этих преимуществ важно как для производителей текстиля, так и для потребителей, которые хотят получить высококачественные изделия из шерсти с длительным сроком службы.

-

Чистота и качество клетчатки

Одно из самых значительных преимуществ карбонизированной шерсти - ее исключительное качество. Процесс карбонизации призван устранить остатки растительного происхождения, семена и другие загрязняющие вещества, которые обычно ассоциируются с сырой шерстью. Это способствует формированию более организованной, линейной системы волокон, что приводит к получению тканей и пряжи высшего качества. Чистота важна не только для эстетики, но и для механической обработки. Более чистые волокна уменьшают количество разрывов, связанных с кардочесанием, прядением и ткачеством, что приводит к равномерной текстуре и внешнему виду ткани. Для областей применения, требующих высокой консистенции, таких как тончайший трикотаж или подходящая ткань, такая степень однородности волокон имеет решающее значение.

-

Надежность и мощность

Карбонизированная шерсть славится своей долговечностью. Удаление загрязнений и усадочные свойства, обеспечиваемые супермойкой, предохраняют волокна от изнашивания и деформации на ранних стадиях. Эти свойства гарантируют сохранение первоначальной формы и мягкости одежды при многократных стирках. Кроме того, карбонизированные волокна реже рвутся и расслаиваются, что делает их идеальными для длительного использования как в одежде, так и в домашнем текстиле. Сочетание долговечности и прочности увеличивает общий срок службы изделий, что приносит пользу потребителям, обеспечивая им функциональность и привлекательность одежды в течение долгого времени.

-

Простота обслуживания и высокая устойчивость к усадке

Натуральная шерсть красива по своей природе и вызывает чувство расслабленности и комфорта, однако обычно требует тщательной стирки или химчистки, чтобы предотвратить образование войлока или усадки. Метод супермойки позволяет преодолеть это препятствие за счет изменения чешуек волокна, что дает возможность подвергать ткань машинной стирке без негативного влияния на ее целостность. Такая простота в уходе является значительным преимуществом на современном рынке, где потребители все больше заботятся об удобстве ухода, но при этом ценят качество. Одежда из карбонизированной шерсти подвержена стирке и сушке с минимальным риском усадки или деформации. Современный образ жизни - это практичность при сохранении природных свойств шерсти.

-

Окрашивание и сохранение цвета

Чистота карбонизированных волокон способствует лучшей реакции на красители, что приводит к яркой, равномерной окраске ткани. Обработка суперстиркой также положительно влияет на окраску, создавая гладкую поверхность волокна, которая способствует равномерному окрашиванию и минимизирует разводы или неравномерность тона. Таким образом, одежда и текстиль остаются визуально привлекательными после многократных стирок. Этот атрибут имеет большое значение для индустрии моды и домашнего текстиля, где точность и постоянство цвета имеют решающее значение для восприятия бренда и удовлетворения потребителя.

-

Разнообразные варианты использования

Еще один положительный аспект карбонизированной шерсти - ее гибкость. Сочетание долговечности, чистоты и простоты ухода позволяет использовать ее для различных целей, включая трикотаж, тканевые костюмы, верхнюю одежду, одеяла и текстильные изделия. Дизайнеры и производители пользуются преимуществами этой гибкости: волокно может адаптироваться как к модным, так и к функциональным изделиям. Его превосходное качество и стабильные характеристики делают его идеальным для комбинирования с другими волокнами, что позволяет создавать новые комбинации тканей с повышенной текстурой, прочностью или эстетической ценностью.

-

Последствия для окружающей среды и устойчивости

Сегодня все большую популярность приобретают современные методы карбонизации и супермойки, которые не наносят вреда окружающей среде. Закрытые системы, химическая обработка на основе энзимов, биоразлагаемые химикаты - все это способствует сокращению химических отходов и расхода воды. Это делает карбонизированную шерсть очень практичным выбором для супермойки. Сочетая превосходные эксплуатационные характеристики с экологически ответственной обработкой, этот материал соответствует глобальной тенденции этичного производства текстиля и привлекает экологически сознательных потребителей.

Применение в текстильной и модной промышленности

Карбонизированная шерсть superwash стала популярным материалом в текстильной и модной индустрии, поскольку сочетает в себе качество, долговечность и простоту в уходе. Его особые свойства способствуют производству высококачественной одежды и текстиля, отвечающих современным стандартам качества и спроса.

-

Индустрия моды

В швейной промышленности карбонизированная шерсть обычно используется для производства одежды высшего качества, в том числе вязаных и тканых изделий, а также пальто и свитеров. Благодаря своим усадочным свойствам и отсутствию войлока она идеально подходит для одежды, которую часто стирают. Высококлассные трикотажные изделия отличаются гладкой текстурой волокна и сохранением цвета, что позволяет изделиям сохранять свою эстетическую ценность на протяжении долгого времени. При изготовлении одежды на заказ карбонизированная шерсть супермойки обеспечивает постоянную длину волокон и равномерное распределение по размерам, что позволяет добиться точного представления ткани и увеличить ее долговечность.

-

Мебель для дома

На внутреннем текстильном рынке также используется карбонизированная шерсть супермытья. Она используется для изготовления одеял, пледов, обивки и других изделий из ткани, где на первый план выходят долговечность и простота ухода. Способность волокна сохранять мягкость и не сбиваться в комки обеспечивает длительный отдых, а его однородность способствует качественной окраске и устойчивости рисунка. Для часто используемого домашнего текстиля, например, чехлов для диванов или покрывал для кроватей, сочетание прочности и удобства стирки является практичным и превосходным решением.

-

Технические и эксплуатационные характеристики tecidos

Помимо модного и домашнего текстиля, карбонизированная шерсть используется в технических тканях для спортивной одежды. Ее способность регулировать температуру в сочетании с термоусадочными свойствами делает ее идеальной для одежды, предназначенной для путешествий, занятий спортом и активного отдыха. Потребителям нравятся влагоотводящие, запахоустойчивые и терморегулирующие свойства шерсти, а производители ценят ее постоянство, долговечность и надежность при использовании в высокотехнологичных изделиях.

-

смешанные волокна

Кроме того, карбонизированную шерсть часто включают в состав других волокон, таких как шелк, кашемир или синтетические волокна, чтобы усилить их специфические свойства. Смешивание позволяет дизайнерам создавать ткани с повышенной мягкостью, растяжимостью или влагоотведением, сохраняя при этом простоту ухода и долговечность карбонизированной супермытой шерсти. Эти смешанные ткани используются в коллекциях с модным дизайном, роскошном текстиле и технической одежде, что повышает популярность этого универсального волокна.

-

Открытость рынка

Растущая популярность элитных, экологичных и не требующих особого ухода текстильных изделий привела к тому, что карбонизированная шерсть стала предпочтительнее других волокон во многих областях. Ее способность сочетать традиционные преимущества шерсти с современной практичностью привлекает как модные бренды высокого класса, так и экологически сознательных потребителей. Ожидается, что по мере того, как в текстильной промышленности будет возрастать значение экологичности и эксплуатационных характеристик, использование супермыла из карбонизированной шерсти будет расти, что укрепит его позиции в качестве важного материала для промышленности.

Преимущества для экологии и устойчивого развития

Сегодня текстильная промышленность озабочена вопросами устойчивого развития и экологической ответственности. Эти два аспекта важны как для потребителей, так и для производителей. Преимущества карбонизированной шерсти superwash очень важны в этом отношении, поскольку ее производство сочетает в себе технологические инновации и экологические практики. Понимание этих преимуществ объясняет, почему этот материал сегодня является предпочтительным выбором для брендов, заботящихся об экологии, и экологически сознательных потребителей.

-

Эффективное использование сырой шерсти

Процесс карбонизации повышает эффективность использования сырой шерсти в качестве ткани за счет удаления нежелательных веществ, семян и растительного материала, которые в противном случае повлияли бы на качество ткани или привели бы к образованию отходов. Благодаря получению более чистых, однородных и карбонизированных волокон метод супермойки гарантирует более высокий выход продукции на этапах прядения, ткачества и окончательной обработки. Такая эффективность снижает потребность в дополнительных поставках сырья, что уменьшает потребление ресурсов и способствует развитию устойчивых методов производства.

-

Сокращение потребления химикатов и воды

Сегодня в современных процессах карбонизации и супермойки все больше внимания уделяется экологически безопасным методам. Например, системы замкнутого цикла утилизируют кислоты, которые используются в процессе карбонизации, что сводит к минимуму попадание химических веществ в сточные воды. Аналогичным образом, ферментативная обработка и биоразлагаемые покрытия для супермойки снижают потребность в агрессивных химикатах. Эти усовершенствования оказывают значительное влияние на экологичность процесса обработки шерсти, сохраняя при этом качество и эксплуатационные характеристики волокон.

-

Долговечность снижает образование отходов

Одежда из карбонизированной шерсти имеет более длительный срок службы, сохраняя свою форму, мягкость и цвет при многочисленных стирках. Такая долговечность снижает частоту смены одежды, что напрямую способствует сокращению отходов. Потребители могут наслаждаться высококачественными шерстяными изделиями на протяжении десятилетий, что снижает воздействие на окружающую среду, связанное с утилизацией одежды и текстильных отходов на свалках.

-

Экологически чистое окрашивание и заключение

Карбонизированные волокна из шерсти однородны и не содержат лишних компонентов, что способствует более эффективному и равномерному процессу окрашивания. Это уменьшает избыточное количество используемого красителя, минимизирует объем потребляемой воды и снижает вероятность повторной обработки из-за неравномерного окрашивания. Кроме того, метод супермойки способствует равномерной и гладкой обработке, что еще больше снижает необходимость использования дополнительных химикатов или этапов.

-

Соответствие тенденциям устойчивой моды

Поскольку экологичность становится важным компонентом принятия решений потребителями, суперстирка из карбонизированной шерсти соответствует этическим экологическим инициативам. Сочетание свойств натурального волокна, простота ухода за ним и снижение воздействия на окружающую среду указывают на бренды, которые поддерживают устойчивое и ответственное производство. Кроме того, использование возобновляемых натуральных волокон, таких как шерсть, в переработанном и ответственном виде поддерживает более широкую цель круговой текстильной экономики.

Сравнение с обычной шерстью и другими видами обработки

Преимущества карбонизированной шерсти superwash становятся более очевидными при сравнении с обычной шерстью и другими традиционными способами обработки. Натуральная шерсть считается теплой, мягкой и воздухопроницаемой, но у нее есть и ограничения, которые влияют на ее полезность, долговечность и уход. Изучив эти противоречия, производители, дизайнеры и потребители смогут понять растущую популярность карбонизированной шерсти в современном текстильном дизайне.

-

Постоянная шерсть

Шерсть состоит из чешуек натуральных волокон, и в ее состав часто входят остатки растительного сырья, семена и заусенцы. Это сохраняет первоначальный состав волокна, но имеет и ряд недостатков.

Усадка и войлок: Необработанная шерсть подвержена ворсованию во время стирки, что может привести к усадке, деформации и снижению долговечности одежды.

Необходимость ухода: Для сохранения формы и мягкости изделия необходима ручная стирка или химчистка; это снижает удобство для потребителя.

Разнообразные характеристики окрашивания: Загрязнения и неровная поверхность волокон могут препятствовать усвоению красителей, что приводит к несовместимости цвета и эстетическим проблемам.

Неэффективность производства: Машины, обрабатывающие необработанную шерсть, с большей вероятностью могут столкнуться с повреждениями волокон, препятствиями и дефектами, что снизит общий выход продукции и увеличит затраты на ее производство.

Хотя обычная шерсть обладает такими природными преимуществами, как теплоизоляция, гибкость и способность удерживать влагу, эти свойства ограничивают ее практическое применение в современном обществе.

-

Обычные тканые и шерстяные материалы

Некоторые обычные процедуры, такие как простая стирка, чистка или базовое смягчение, могут улучшить качество шерсти. Однако в них редко рассматриваются все критические факторы сразу. Например, вычищенная шерсть содержит некоторые загрязнения, но не предотвращает войлочность и усадку. Стандартное смягчение улучшает управляемость ткани, но не оказывает существенного влияния на насыщенность и долговечность цвета. Напротив, карбонизированная шерсть супермойки обладает множеством преимуществ в одном материале.

-

Преимущества карбонизированной шерсти многочисленны.

Сочетая процесс карбонизации с супермойкой, обработанная шерсть приобретает преимущества как обычного, так и традиционного процесса:

Чистота волокна: В процессе карбонизации очищаются семена, кусочки фруктов и растительный материал, что позволяет добиться однородного качества волокна.

Устойчивость к усадке: Обработка Superwash изменяет состав волокон, что позволяет стирать без образования войлока.

Легкость в уходе: одежда проста в уходе и не требует особого внимания.

Прочность и долговечность: волокна сохраняют мягкость, форму и прочность при многократных стирках.

Постоянное окрашивание и окончательная обработка: Равномерные волокна обеспечивают яркий, ровный цвет и гладкую текстуру.

Универсальность: Подходит для изготовления одежды высокого класса, трикотажа, тканей для выступлений, домашнего текстиля и смешанных материалов.

-

Последствия для рынка

С точки зрения потребителя, супермохнатые изделия из карбонизированной шерсти выгодны как производителям, так и потребителям. Производители получают удовольствие от повышения эффективности производства, уменьшения количества проблем и стабильного качества. Потребителям нравится покупать долговечную, простую в уходе и качественную одежду, которая сохраняет свой внешний вид на протяжении долгого времени. Такое сочетание преимуществ привело к популяризации карбонизированной шерсти в качестве компонента элитной моды, домашнего текстиля и технологических разработок.

Заключение

Карбонизированная шерсть супермойки представляет собой будущее обработки шерсти, сочетая традиционные удовольствия с современными достижениями. Благодаря передовой обработке и защитным средствам он обеспечивает превосходную мягкость, чистоту и долговечность. Для брендов, которые хотят создавать высококачественные шерстяные ткани, не требующие особого ухода и обладающие высокой степенью привлекательности для покупателей, этот материал идеально подходит.

Для чего бы ни предназначалась эта ткань - для моды, домашнего текстиля или промышленного использования, - карбонизированная шерсть супермохнатой выделки способна обеспечить в одной ткани производительность, эстетику и экологичность. Эта ткань по-настоящему переосмысливает то, какой может быть современная шерсть.