Abstract:

Wool fabric is commonly recognized for its intrinsic softness, thermal regulation, and durability; however, it also needs to be maintained with care in order to preserve its capabilities and longevity. A common query between consumers and professionals in the textile industry is whether or not fabric softener is safe to use on wool.

According to Textile Science and Technology by Morton & Hearle, Wool: Science and Technology by Simpson & Crawshaw, and guidance from organizations like The Woolmark Company, conventional fabric softeners are typically not appropriate for wool fabric due to their chemical association with the fibers.

This article discusses the composition of wool fabric, the way in which fabric softeners function, the dangers associated with their utilization on wool, and alternatives that are approved by the industry.

Introduction: Why Wool Fabric Care Matters

Wool fabric has been utilized for millennia; it’s valued for its durability, stretchiness, moisture management, and natural coziness. Unlike synthetic fibers, wool is a protein-based natural fiber that is primarily composed of keratin. This characteristic contributes to its unique properties; however, it also makes it susceptible to chemical treatments.

Today, consumers are inclined to utilize fabric softeners on cotton or other synthetic clothing to enhance the feel of the hand and reduce static. However, applying the same methods to wool fabric can lead to unfortunate consequences, including fiber loss, decreased breathability, and reduced lifespan of the garment.

This poses a significant question that is frequently asked: Can you utilize fabric softener on wool? To answer the question accurately, we must first understand the makeup of wool fabric and the way in which fabric softeners interact with textile fibers at the molecular level.

Understanding Wool Fabric: Fiber Structure and Properties

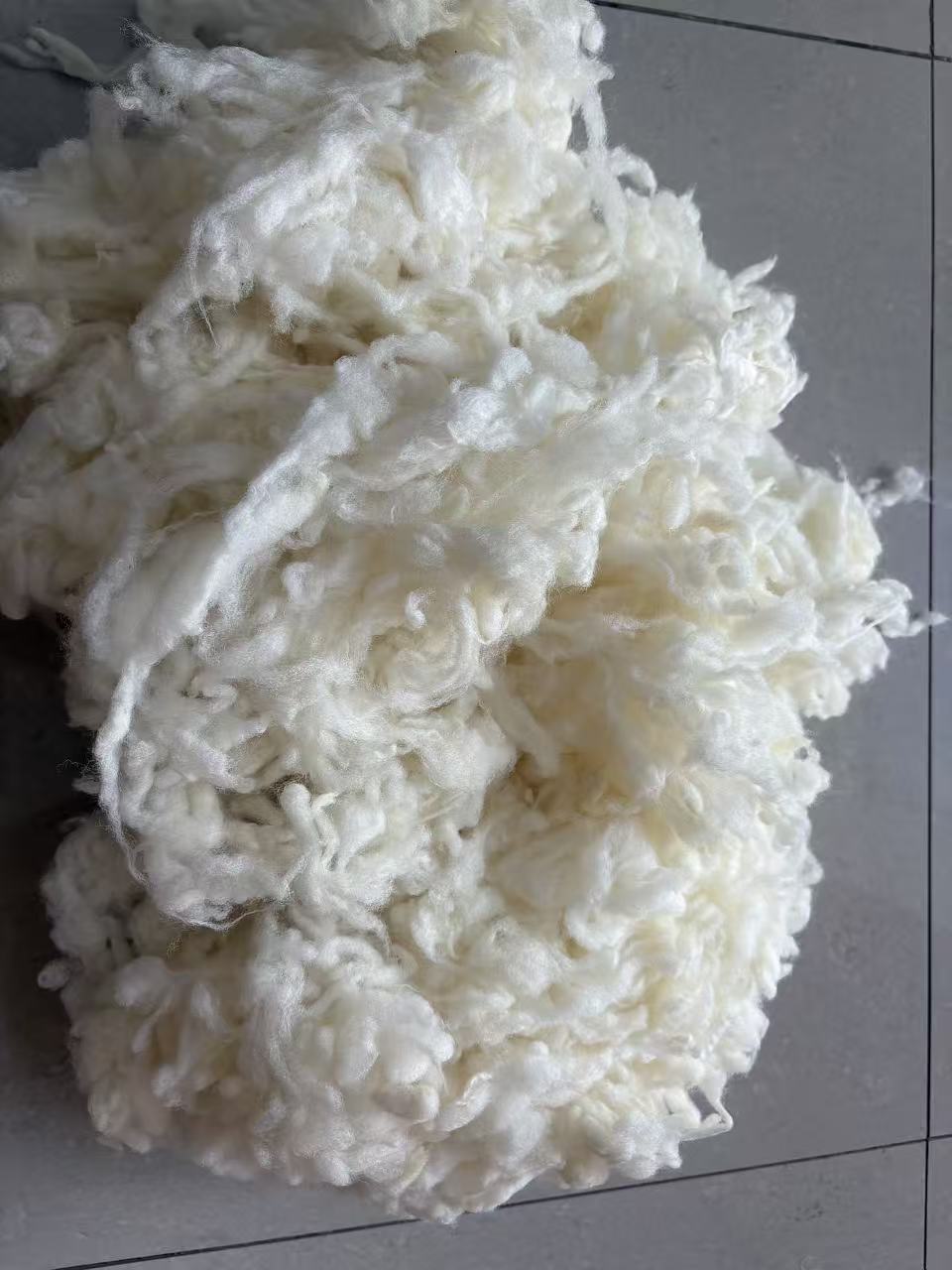

Wool fabric is composed of animal hair fibers, which are typically sheep’s wool. Its composition is markedly different from fibers derived from plants or synthetic materials.

Main characteristics of wool fabric:

Scaly cuticle layer: Overlapping cells of the cuticle serve as a barrier to prevent exposure of the fiber to chemicals or vibrations, but are also sensitive to these two.

Crimped fiber architecture: Natural flexibility promotes stretchiness, insulation, and weightlessness.

Intensive interior: The wool can hold up to 30% of its weight in water without becoming soaked.

Keratin protein composition: Capable of being harshly affected by alkaline conditions and harsh chemicals

These properties explain the different behavior of wool fabric during washing and drying.

How Fabric Softeners Work?

Fabric softeners are intended to alter the surface of textile fibers, primarily to enhance softness and reduce static electricity.

Common functions of fabric softeners:

Provide fibers with supplementary agents that lubricate.

Reduce the amount of friction between the different parts of the fabric.

Drainage of static electricity

Increased drape and enhanced feel

Many popular fabric softeners utilize cationic salts, silicones, or fatty acid compounds. These substances have a strong affinity to cellulose fibers like cotton and other synthetic fibers, but they are not chemically compatible with wool fabric.

Why Fabric Softener Is Not Recommended for Wool Fabric?

- The interaction between chemicals and wool’s keratin is

Wool fibers are amphoteric, which means they can interact with both acidic and alkaline substances. Many fabric softeners have a chemical composition that alters the surface chemistry of the fabric; this is likely to lead to the weakening of the fabric over time.

- The slicing process causes the skin to have a damaged CuticleLayer

The scaly fabric’s cuticle is crucial to its strength and moisture regulation. Fabric softeners can:

Flatten or decimate the scales of the cuticle.

Increase the likelihood of felting during subsequent washes.

Reduce the stretchiness of fibers

This damage is typically permanent.

- Reduced Breathability and Moisture Management

One of wool’s most beneficial properties is its capacity to regulate temperature and moisture. Softener leftovers create a coating on the fiber’s surface that can:

Prevents the absorption of moisture

Reduce the transmission of vapor

Reduce the thermal comfort

For those who wear wool-based clothing, this is a significant downside.

- Increased Pilling and Fiber Slippage

Contrary to popular belief, fabric softeners may cause the wool fabric to have more pilling by overzealous lubrication, which will facilitate the migration and tangling of the fibers during wear.

Industry Guidance: What Textile Authorities Say?

The Woolmark Company is one of the most prominent organizations devoted to wool science. They specifically caution people about using conventional fabric softeners on wool clothing. Their standards of care focus on the stability of fibers, the preservation of dimensional properties, and the integrity of performance, all of which are susceptible to softening.

Similarly, studies that have been peer-reviewed in the Textile Research Journal have demonstrated that the repeated use of softeners on protein fibers can adversely affect their tensile strength and surface resilience.

Are There Any Exceptions?

Some products are marketed as being wool-friendly or fabric conditioners for wool; these products are said to be safe substitutes. These products are typically different from common softeners in several ways:

Nontoxic, cationic preparations

Profiles that are pH-balanced or only marginally acidic.

Absence of large silicones

However, even these products should be utilized with caution and first tested on small regions.

Approved Alternatives to Fabric Softener for Wool Fabric

- Wool-Protein Detergents

Wool detergents are intended to remove grease without destroying natural oils or damaging the keratin. They typically have:

Low surfactants

Fiber-protective compounds

Acceptable acidity or neutrality, with a slight slope.

- Use of vinegar as a Rinse-Aid

White vinegar is occasionally employed as a natural counterpart. It assists in the removal of detergent’s residue and restores the softness of the fibers without covering the fabric in wool.

- Effective Washing Technique

Longevity and softness are typically more effectively achieved through proper care methods, including:

Cool or warm water

Gentle escrima

Minimal number of spin cycles

Comparison Table: Fabric Softener vs Wool-Safe Alternatives

| Аспект | Conventional Fabric Softener | Wool-Specific Detergent | Vinegar Rinse |

| Compatibility with wool fabric | Poor | Превосходно | Хорошо |

| Effect on fiber structure | Potential damage | Protective | Neutral |

| Breathability impact | Reduces | Maintains | Maintains |

| Risk of residue buildup | Высокий | Низкий | Очень низкий |

| Recommended by wool authorities | Нет | Да | Conditional |

Common Misconceptions About Wool Fabric Softness

Wool is frequently misinterpreted as being soft. While traditionally associated with warmth and long life, modern wool fabric can be exceptionally soft and inviting. Many common misconceptions still persist because of outdated information or a poor understanding of wool fiber technology.

Misconception 1: All wool products are scratchy.

This is one of the most commonly disregarded myths.

In reality, itchiness is derived from the fiber diameter, not the presence of wool as a fabric. Fine wool fibers (such as Merino wool) tend to bend easily against the skin, which diminishes the irritation associated with them. Coarser wool fibers, which are commonly employed in carpets or outerwear, are more likely to have a feel.

Key information: Wool that is less than 24 microns is typically considered to be soft and skin-friendly.

Misconception 2: Wool is typically tough and rough.

Modern methods of processing wool, such as the superwash treatment, the enzymes that are used, and the advanced spinning, have greatly enhanced the softness of wool. These methods smooth the fiber’s scales and increase flexibility, which results in a softer hand feel that is comparable to premium cotton or synthetic fabric.

Misconception 3: Soft Wool Isn’t Resistant

Softness is not synonymous with weakness. The wool fibers have a high elasticity and are resilient, even when they are extremely spun. High-end soft fabric can maintain its shape, resist wrinkling, and last through multiple uses without negatively impacting comfort.

Misconception 4: The Wool Softness of the Product decreases over time.

Cared-for wool that is properly treated will often become softer with time, rather than harder. Natural fiber elasticity promotes the relaxation of wool clothing over time; this is especially true of garments that are washed and stored appropriately.

Falsehood 5: Wool is less comfortable than synthetic fibers.

While some synthetic fibers seem to have a smooth initial feel, wool has superior moisture management, breathability, and temperature regulation. These properties facilitate long-term relaxation, which is ideal for base layers, knittedwear, and next-to-skin clothing.

Misconception 6: The Wool Softness Is Constant across All Products.

Not all wool fabric is created with the same level of porosity. The softness of the clay is dependent on the following:

Breeders of wool and finely-fleshed fibers

The design of the yarn and the creation of the fabric.

Complete treatments

End-of-life application

Understanding these factors will assist buyers in selecting wool fabric that satisfies comfort desires.

Industrial and Commercial Perspectives

The fabric made of wool continues to have a significant impact in both commercial and industrial settings. This is attributed to the unique combination of properties, sustainability, and aesthetic value. From technical fabric to superior apparel, wool continues to be a material that is strategically significant in global supply chains.

- Commercial uses of wool fabric

In the industry, wool is considered more important for its functional capabilities than its appearance.

Protectively clothed: Natural flame resistance and thermal insulation in wool make it ideal for wear, military uniforms, and firefighters’ gear.

Sound-absorbing and insulation materials: The wool’s flocked fiber composition enables the absorption of sound and provides effective thermal insulation in buildings and vehicles.

Filtration materials: Wool fibers are employed in the air and water filtration processes because of their moisture-absorption capacity and resilience.

Industrial felts: They’re commonly employed in the field of sealants, polishes, vibrations, and machinery components.

These uses of wool are facilitated by its durability, stretchiness, and resistance to static electricity.

- Business and Fashion Markets

In business areas that involve wool, it is considered a premium material that is performance-driven.

Fashionable and luxurious apparel: Fine and Merino wool serve as the core of suits, coats, knittedwear, and custom apparel.

Corporate and standard textiles: Wool combinations provide stability, comfort, and a professional appearance that will last over time.

Home textiles: Carpets, rugs, blankets, and upholstery enjoy the resilience of wool and the natural resistance to stains.

The differentiation of brands is often based on the wool’s comfort, breathability, and value over time.

- Supply Chain and Source Control Ideas

From a business perspective, finding wool fabric that is sourced requires focus on the following:

Fiber quality and consistency: The number of microns, the length of staples, and the origin of the product’s pricing and performance are all considered.

Processing standards: Spinning, weaving, and finishing methods influence hand feel and durability

Trackability and certification: Programs like RWS (Responsible Wool Standard) and OEKO-TEX® increase the credibility of the market.

Stable costs: The price of wool is dependent on the climate, management of livestock, and demand across the globe.

Strategic sourcing is employed to ensure that quality expectations are met while still maintaining a viable commercial endeavor.

- Sustainability and the Marketplace

The concept of wool as a sustainable and circular material is increasing in popularity.

Biomimetic and environmentally friendly fiber

A long service life increases the frequency of replacement.

Lower concentrations of microplastics as compared to synthetic fibers.

These traits concur with corporate goals regarding sustainability and evolving consumer preferences.

- Advantages in modern markets that are competitive

From a commercial perspective, wool has specific benefits:

All-natural properties that lack harsh chemicals.

Adaptability to combinations of synthetic fibers or other natural fibers

A powerful marketing strategy in the premium and value-added segments.

As environmental concerns and durability increase, wool is still economically significant.

Экологические соображения

- Biomorphic and biodegradable fiber

Wool is a naturally occurring fiber that is cultivated every year on sheep by biological processes that are intrinsic to the animal. Unlike other synthetic fibers that are derived from fossil fuels, wool is naturally biodegradable; it will decompose in soil and marine habitats without releasing any large microplastic particles that are resistant to biodegradation.

Environmental Benefit: Reduced long-term pollution and less dependency on non-renewable resources.

- Low Microplastic pollution

Unlike polyester or nylon, the wool fibers do not release microplastic shedding during washing or use. Any fibers that are released are naturally occurring proteins that degrade naturally, which minimizes the environmental impact on waterways.

Environmental Help: Cleaner oceans and a lower microfiber load.

- The amount of energy and resources devoted to processing is significant

The processing of wool involves less energy than the creation of synthetic fibers; this is especially true of the polymerization stage. However, the environmental impact is different depending on this:

Farming methods

The effectiveness of scouring (washing) processes

Dyeing and finalizing methods

Today, wool producers that are modern tend to utilize closed-loop water systems and low-emission dyes in order to minimize environmental impact.

- Carbon and Climate Impact

Sheep farming is associated with carbon dioxide emissions, particularly methane. However, wool’s fibers store carbon during their lifetime, and effective land management can mitigate the release of carbon through enhanced soil health and carbon storage.

Key Insight: Sustainably designed wool systems can help to contribute to carbon-neutral or low-impact production.

- Product Lifespan and Durability

Wool clothing is associated with a long lifespan, natural elasticity, and resistance to odors, all of which reduce the need for frequent cleaning and replacement. Products’ longer lifespans have a direct impact on the environmental impact overall.

Environmental Help: Reduce trash and consumption.

- Accountable Wool Rules and Licensings

Environmental and ethical behavior is increasingly recognized through certifications like this:

RWS (the standard responsible for wool)

ZQ breed

Organic Wool Rules

OEKO-TEX®

These initiatives promote animal comfort, land stewardship, and accountability.

FAQ: Fabric Softener and Wool Fabric

Q1: Is it possible to use fabric softener on wool fabric?

Typically, no. Conventional fabric softeners are not advisable for wool fabric because of the potential fiber damage.

Q2: What occurs if you utilize the wrong amount of fabric softener on wool?

Occasional use may not lead to immediate harm, but repeated use may lead to a decrease in softness, stretchiness, and breathability.

Q3: Does fabric made of wool have a naturally soft texture?

Yes. High-quality fabric derived from wool, especially fine Merino wool, is inherently pleasant when treated and cared for properly.

Q4: Are “wool conditioners” distinct from fabric softeners?

Yes. Conditioners made of wool are typically softer, have a pH of 7.8-7.9, and are specifically formulated for the protein fibers in wool.

Q5: How can I make wool clothing feel more inviting?

Use wool-specific cleaning agents, avoid over-drying, and allow clothing to rest between uses in order to regrow its original elasticity.

Заключение

Can you utilize fabric softener on wool? From a scientific and business perspective, the answer is typically no. The unique protein-based composition of wool fabric makes it resistant to the effects of conventional fabric softeners; these chemicals can degrade the fiber’s integrity, comfort, and longevity.

By understanding the behavior of wool fabric and following the rules of textile design, manufacturers and consumers can preserve the natural benefits of wool, including its softness, breathability, durability, and sustainability, without having to rely on chemical agents to soften it.

Proper care is not about increasing the number of treatments, but rather respecting the natural capabilities of wool fabric.