Article Summary:

The wool fabric has been a significant component of the textile industry throughout human history. It’s valued for its thermal insulation, moisture control, durability, and natural resilience.

According to the authoritative textile science references mentioned above, such as Textiles: Fiber to fabric (Corbman), Wool: Science and Technology (Woodhead), and the International Wool Textile Organization’s (IWTO) publications, wool can be classified into three different types based on the fiber’s origin, fineness, and performance at the end of use.

This article provides a comprehensive, industry-oriented description of the three primary types of wool fabric: Merino, coarse (or longwool) wool, and specialty wool. It analyzes the fiber composition, processing attributes, performance properties, and commercial potential of these fabrics.

Why Understanding Wool Types Matters in the Textile Industry?

Despite the common perception that wool is a singular fabric type that consumers often treat as such, the textile industry regards wool as being composed of a highly diverse group of fibers. Different types of wool have different amounts of wool:

- Fiber length

- Constant length

- Frequencies below which crimp occurs

- Scale of the surface area

- Mechanical resistance

These discrepancies directly affect the methods of spinning, fabric creation, processing, and final performance. From a sourcing and product development perspective, choosing the wrong type of fabric can lead to financial inefficiencies, discomfort, or early failure of the product.

Understanding the three primary types of wool provides a basic framework for dealing with this complexity.

How Wool Is Classified: Industry Perspective?

Wool can be categorized in multiple ways, including by animal species, fiber diameter (micron count), or intended use. However, the majority of textile engineering literature focuses on a functional classification that categorizes wool into three primary types.

Fine wool ( Merino wool )

Fine to medium wool (crossbred and longwool types)

Unique wool types (cashmere, alpaca, mohair, etc.)

This classification concords with the behavior of fiber processing and the performance of fabric; this is significant for the industrial and commercial uses of wool fabric.

Type One: Merino Wool (Fine Wool)

- Fiber Properties

Merino’s wool is considered the most luxurious and versatile of all wool types. Originally derived primarily from Merino sheep, this wool has the following properties:

- The diameter of fibers is typically between 15 and 24 microns.

- Elevated frequency of crimp

- Soft touch and exceptional stretchiness

The fine fiber diameter of the Merino breed’s wool decreases the skin’s irritation, which makes the wool of the Merino breed suitable for clothing that is near the body.

- Fabric Performance

The Merino wool fabric has a unique combination of attributes:

- Excellent thermal insulation

- High water vapor intake (up to 30% of its weight without having to feel wet)

- Ability to withstand natural odors

- superior fabric and mobility

From a fabric design perspective, the high degree of crimp increases the volume of air in the fabric, which enhances insulation while still allowing breathability.

- Common Examples

Merino’s wool is typically employed in fabric production.

High-end clothing

Base layers and activewear

Custom suits

Extravagant knittedwear

Its versatility across both woven and knitted structures makes it one of the most profitable types of wool for commercial use.

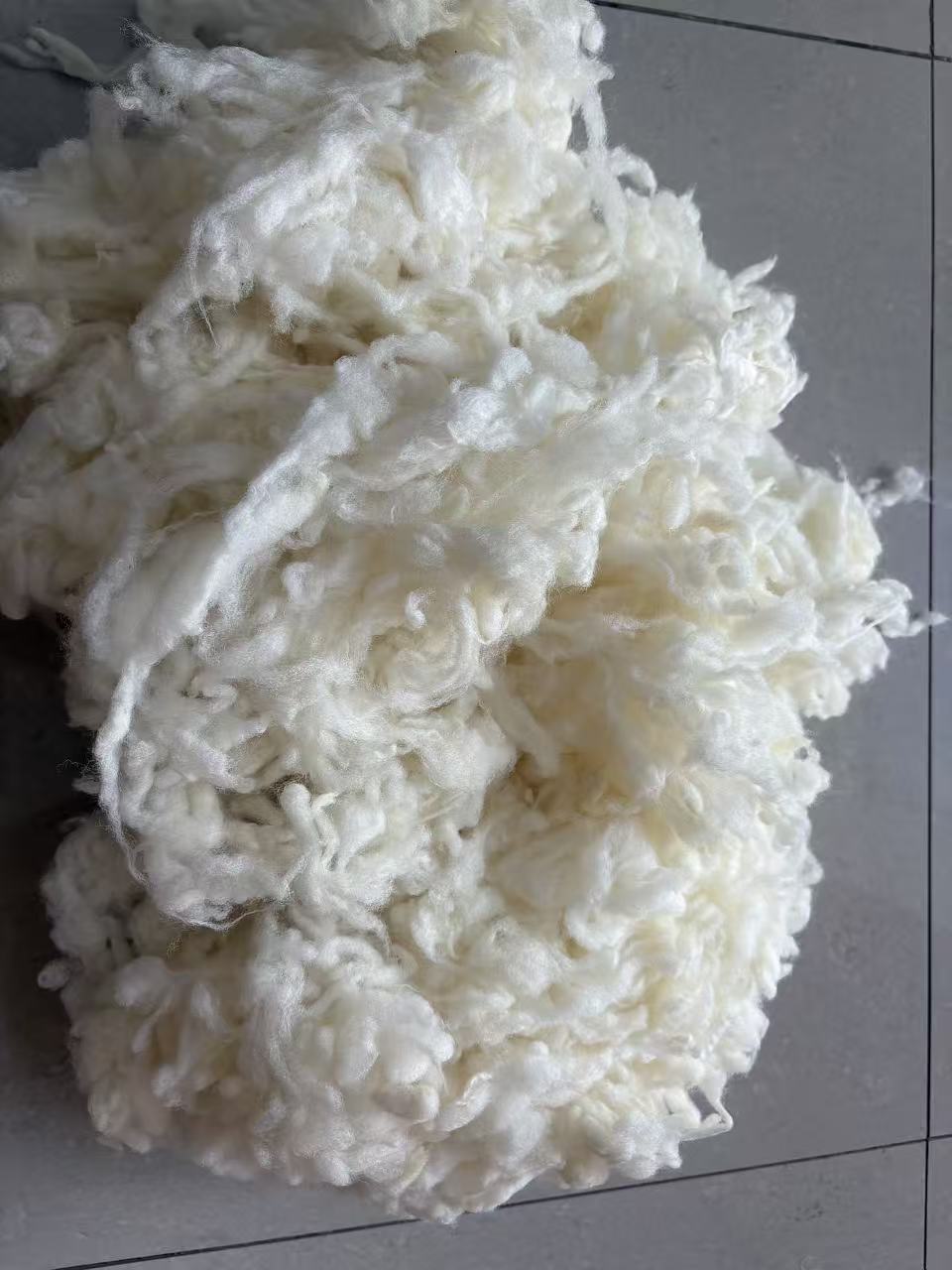

Type Two: Coarse and Longwool (Crossbred Wool)

- Fiber Properties

Crude wool, which is often derived from crossbred sheep, has fibers with diameters that are typically larger than 25-40 microns. Longwool varieties produce fibers that have a longer staple and have a lower crimp.

Compared to fine wool fibers, coarse fibers are:

- Thicker

- Stronger

- Less flexible

These attributes have an effect on both the efficiency of spinning and the behavior of the fabric as it is finished.

- Fabric Performance

Coax fabric that is too coarse for the intended use prioritizes durability and structural integrity over softness. While it may seem to be more difficult to apply it against the skin, it is superior in:

- Abrasion resistance

- Stability in terms of dimensions

The long term performance of the product

The decreased crimp causes the fabric to have a firmer texture that is well-suited to stress.

- Common Examples

Coaxing fabric is commonly employed in:

- Carpets and rugs

- Blankets

- Upholstery fabric

- Outfits and accessories for work

In manufacturing contexts, the type of wool fabric that is categorized as being essential continues to be important.

Type Three: Specialty Wool

What is specialty wool?

Specialty wool is characterized by fibers derived from animals other than common sheep or specialty breed animals. Common instances include:

- Cashmere (goat)

- Mohair (Goat from Angora)

- Alpaca and llama

- Angora goat

These fibers are frequently incorporated into sheep’s wool to augment specific properties of fabric.

- Fiber Properties

Specialty fibers derived from wool are diverse, but are typically characterized by:

- Very small diameters

- Smoothed surface slopes

- High gloss

For instance, cashmere fibers typically have a diameter of 14-19 microns, which makes them smaller than the majority of Merino fibers.

- Fabric Performance

Specialty wool fabric is associated with:

- Exceptional sluggishness

- Heavierweight insulation

- Increased aesthetic value

However, these fibers have a lower stretchiness and are prone to processing.

- Common Examples

Specialty wool fabric is primarily employed in:

- Extravagant clothing

- Scarves and shawls

- High-end fashion

- High-end blends for fashion fabric

Because of the limited supply, specialty wool fabrics’ prices are higher.

Comparison Table: The Three Main Types of Wool Fabric

| Wool Type | Fiber Diameter (Microns) | Key Properties | Common Applications |

| Merino Wool | 15–24 | Soft, elastic, breathable | Apparel, activewear, suits |

| Coarse / Longwool | 25–40+ | Strong, durable, stable | Carpets, blankets, outerwear |

| Specialty Wool | 14–30 (varies) | Luxurious, lightweight, soft | Luxury garments, blends |

Fiber Structure and Its Impact on Wool Fabric Performance

The quality of wool fabric is primarily derived from the fiber’s shape. The wool fibers’ complex composition comprises:

Cuticle (outer skin layer)

Cortex (inner part of the brain that controls wrinkling and stretchiness)

Fine wool fibers have a higher frequency of crimps, which increases the elasticity and softness of the fabric. Coarse fibers have fewer crimps, which results in a stiffer fabric.

This structural difference is responsible for the fact that the diameter of fibers is one of the most important factors in the selection of wool fabric.

Spinning and Manufacturing Considerations

Different types of wool have different requirements for spinning:

- Merino wool is typically spun through worsted or semi-worsted mechanisms.

- Frequently, wool that is too large or too small is processed via woolen cultivation.

- Specialty wool is often characterized by low tension in the spinning process to avoid fiber injury.

The compatibility of manufacturing directly affects the uniformity of yarns, the strength of fabric, and the efficiency of production.

Dyeing and Finishing Behavior of Wool Fabric

Wool fabric dyes readily due to its protein-based chemistry. However, fiber type influences:

- Dye uptake rate

- Color depth

- Shrinkage behavior

Fine wool fabrics are more sensitive to heat and agitation, requiring controlled finishing processes such as superwash treatments for machine washability.

Comfort, Breathability, and Thermal Regulation

All types of wool have a natural ability to regulate their temperature, but the capacity to do so is variable:

- Merino’s wool is exceptional in providing next-to-skin comfort.

- Coaxing wool serves as insulation in bulk.

- Unique fibers provide warmth while minimizing weight.

These attributes wool uniquely attuned to different climates and categories of products.

Durability and Lifecycle Performance

From a lifecycle perspective:

- Coarse wool fabric often lasts the longest in high-wear environments

- Merino wool balances comfort and longevity

- Specialty wool requires careful handling but delivers premium value

Understanding lifecycle expectations is crucial for B2B buyers and designers.

Sustainability and Environmental Considerations

Wool fabric is comprised of:

- Renewable

- Biodegradable

- Naturally reusable

However, the sustainability of farming practices and the processing of goods varies. Certifications like RWS (Responsible Wool Standard) are becoming more important in the sourcing process.

Market Demand and Commercial Trends

Global demand for wool fabric continues to grow in:

- Performance apparel

- Sustainable fashion

- Interior textiles

Merino wool dominates volume markets, while specialty wool drives value growth.

Common Misconceptions About Wool Types

A common misconception is that all wool clothing is scratchy. In reality, the diameter of the fiber determines the level of comfort.

Another misconception is that specialty wool is always superior to Merino wool; however, the latter is performance- dependent.

How to Choose the Right Wool Fabric for Your Application?

Key decision factors include:

- End-use requirements

- Skin contact level

- Durability expectations

- Budget constraints

Aligning these factors with the correct wool type ensures optimal performance and customer satisfaction.

FAQ: Wool Fabric

What are the three primary types of wool?

The three primary types are Merino wool (low-fat), longwool, and specialty wool.

Which fabric made of wool is most beneficial for clothing?

Merino fabric from wool is typically most beneficial for clothing because of its softness, stretchiness, and breathability.

Is it beneficial to have specialty fibers over the long haul?

Not necessarily. Specialty fibers offer luxury and softness, while Merino fibers have a more diverse array of properties and are more durable.

What type of fabric is most beneficial for carpets?

Coaxing the wool into fabric is most effective for carpets, as it has a strength and abrasion resistance similar to that of coarse fabric.

Is the wool fabric environmentally friendly?

Yes. Wool fabric is renewable, biodegradable, and can be recycled when sought out carefully.

Conclusion

Understanding the three primary types of wool is crucial to anyone involved in the manufacturing of textiles, finding a source of wool, or developing a product. Every type of wool fabric has its own advantages that are derived from the fiber composition and behavior during processing.

Instead of viewing wool as a singular entity, professionals in the industry should consider wool fabric as a material system that is strategic in nature; they should select the appropriate type of fabric to balance comfort, durability, sustainability, and cost.