Carbonised wool superwash fabric is a highly finished textile material combining the traditional process of wool purification with an advanced treatment process of superwash. Therefore, the resultant wool fabric becomes cleaner, softer, more uniform, and much easier to handle than any conventional type of wool fabric. Its application lies within modern clothing and knitwear fabrics and garments that require construction for strength, together with ease in caring for them.

With the high quality and minimum requirement for easy care of natural fibers in global textile markets, carbonised wool superwash fabric has been increasingly highlighted. It therefore acts as an important link between the luxury characteristics associated with wool and practical modern consumer demands, wherein it can be used both in common apparel as well as premium fashion applications.

This article contains a detailed description of what carbonised wool superwash fabric is, how it is made, basic characteristics, practical uses, benefits, and drawbacks, as well as its place in the current development of textiles and apparel.

Understanding Carbonised Wool Superwash Fabric

Carbonisation and superwash are the two main processes involved in the production of carbonised wool superwash fabrics. Each process separately contributes to improving the quality as well as facilitating the use of wool fibers; they help in the transformation of raw wool into a contemporary high-performance textile.

Carbonisation focuses on the removal of impurities from the wool. Superwash treatment improves washability and dimensional stability. A fabric is created that maintains the natural benefits of wool but overcomes many of its traditional shortcomings.

What Carbonisation Means in Wool Processing

Carbonisation is a special chemical process of purification mainly directed at wool with large contents of vegetable matter. These are usually burrs, seeds, straw, grass parts, and other plant residues that lodge in the fleece as sheep feed over natural pastures.

During carbonisation, wool is treated with a carefully controlled solution of acid, most commonly sulfuric acid. This acid has a reaction with cellulose-based plant matter, but very little effect on the protein-based wool fiber. The vegetable matter is turned into brittle, carbonised particles.

The mechanical impurities are removed by agitation, crushing, or shaking after carbonization. The wool fibres remain unbroken but are left in a state of cleanness and great uniformity. This step of purification is very important in the production of fine textiles, light colored fabric, and high-quality yarns.

What Superwash Treatment Adds to Wool

Superwash is a contemporary term describing a finish applied to make the wool machine washable and resistant to shrinkage. Wool fibers, even after being processed into yarn or fabric, have microscopic surface scales visible under powerful magnification. These scales interlock when exposed to heat, moisture, and agitation(techno-scientific term for movement), hence felting; therefore, totally irreversible shrinkage.

The superwash process either smooths the scales of the fiber by a controlled chemical treatment or deposits a thin polymer coating film, which will prevent the fibers from interlocking. Certain processes perform both actions for maximum effect.

Superwashed wool can be washed and will not shrink, become misshapen, or lose its softness to any appreciable degree. This makes wool clothing usable in practical terms for everyday wear.

Why Carbonisation and Superwash Are Combined

Carbonisation is for purity, cleanliness, and appearance consistency of the fiber, while superwash treatment is for strength, washability, and dimensional stability. The two treatments are found in most high-quality, reliable, easy-care fabrics to meet, to a large extent, modern industry standards that emphasize such attributes. This makes carbonized wool a superwash fabric perfectly suited not only for massive apparel production but also for export markets.

How Carbonised Wool Superwash Fabric Is Made

The production of carbonised wool superwash fabric involves a series of carefully controlled steps, each of which contributes to the final fabric’s performance, appearance, and longevity.

Raw Wool Selection and Preparation

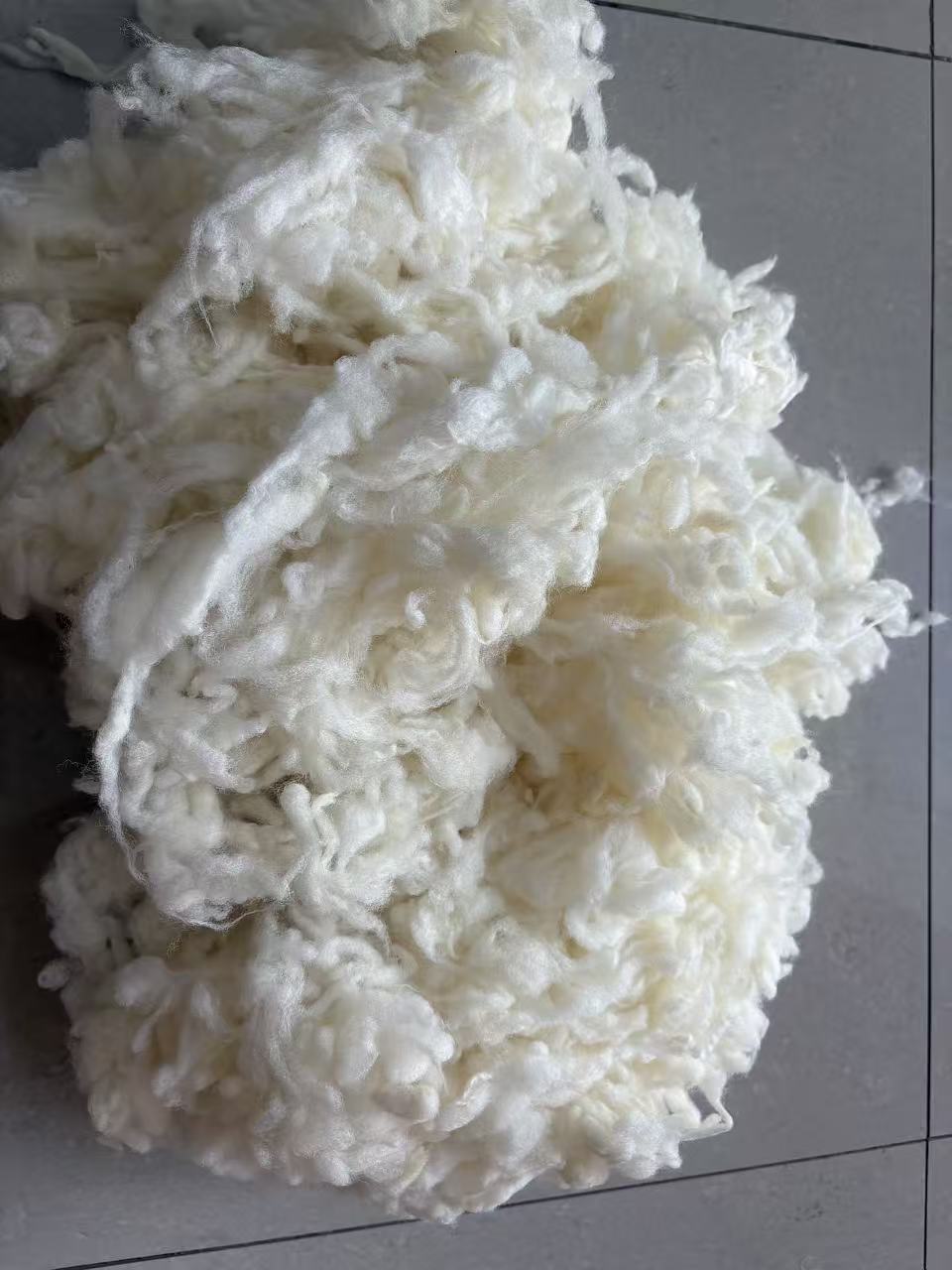

The process begins with the selection of raw wool-often sourced from regions where sheep grazing conditions lead to higher levels of vegetable contamination. Such wool may be unsuitable for high-end applications in its raw state, but it can be transformed through carbonisation.

Prior to carbonisation, the wool is sorted for length of fibre, fineness, and quality. It is then scoured to remove natural grease, dirt, and sweat, and opened and blended to facilitate uniform treatment in later processes.

The Carbonisation Process

The wool that has been prepared is soaked in a diluted acid solution during carbonisation. The acid reacts selectively toward the plant-based impurities without much reaction to the wool fibers themselves. After soaking, it is dried and heated so that the vegetable matter carbonises within it, then becomes brittle,

The wool is then neutralized and well-washed to remove all traces of acid so that the fibres are left safe, sound, and suitable for further processing.

Spinning and Fabric Formation

After carbonisation, the wool is spun into yarn by a method selected in relation to the characteristics of the fabric eventually desired. Woolen spinning imparts softer and bulkier yarns; worsted spinning provides smoother and finer yarns with strength and greater definition.

The fabrics may be either knit or woven from these yarns. More commonly, carbonised wool superwash fabric is used in knit structures-in jerseys, ribs, and interlocks- but it is also woven for use in more structured garments.

Application of Superwash Treatment

The treatment is applied to the fabric. A good result will show the balance between shrink resistance and softness, added together with breathability. Then it will be rinsed, dried, andundergo another stabilization process to keep its performance repeatable.

Tests on finished fabrics for dimensional stability, surface appearance, and hand feel approval are conducted before being made into garments.

Key Properties of Carbonised Wool Superwash Fabric

Carbonised wool superwash fabric offers a well-rounded combination of natural and engineered properties that make it suitable for a wide range of applications.

Clean and Uniform Appearance

Due to the removal of vegetable matter during carbonisation, the fabric has a clean surface free from dark specks and irregularities. This uniformity improves visual quality and makes the fabric particularly suitable for light shades and fine-gauge constructions.

Softness and Wearing Comfort

The combination of purified fibers and surface modification results in a softer hand feel compared to traditional wool. This enhanced comfort makes the fabric suitable for garments worn directly against the skin.

Shrink Resistance and Shape Stability

One of the defining features of carbonised wool superwash fabric is its resistance to shrinkage. The fabric maintains its original dimensions and shape even after repeated washing, reducing the risk of garment deformation.

Moisture Management and Thermal Regulation

Despite chemical processing, the fabric retains wool’s natural ability to absorb moisture, regulate body temperature, and provide breathability. These properties contribute to comfort across a range of environmental conditions.

Durability and Reduced Pilling

The cleaner fiber structure and stabilized surface reduce friction and fiber breakage, resulting in improved durability and reduced pilling over time.

Applications in Apparel and Textiles

Carbonised wool superwash fabric is used across multiple apparel categories due to its versatility and dependable performance.

Knitwear and Sweaters

The fabric is widely used in sweaters, cardigans, pullovers, and fine-gauge knitwear. Its softness, consistency, and washability make it ideal for both casual and premium knit collections.

Dresses and Fashion Garments

In fashion applications, the fabric provides a refined drape and smooth appearance. It accepts dyes evenly, allowing for rich and consistent color development.

Suits and Tailored Clothing

When woven, carbonised wool superwash fabric is used in suits, skirts, and structured garments. The purified fibers contribute to a smooth surface and professional appearance.

Base Layers and Everyday Apparel

The fabric’s comfort and easy-care properties make it suitable for base layers, lightweight tops, and everyday garments designed for frequent wear.

Advantages Over Traditional Wool Fabrics

Superwash carbonised wool fabric provides extremely substantial, practical, and aesthetic benefits over the untreated wool fabric.

It can be easily cared for since it allows repeat machine washing without shrinking. It appears cleaner, more consistent, and has better durability, which removes all the usual complaints that consumers have regarding garments made of wool.

This gives greater design flexibility to manufacturers while enhancing convenience and comfort to the consumer.

Limitations and Considerations

There are still some limitations to the extra processing steps that add to the production cost, which may reflect on pricing in markets where sensitivity to costs is high. This largely pertains to environmental considerations of chemical use during processing. The impact on the environment can be well controlled if responsible manufacturing practices are used together with proper treatment of wastewater before its discharge into water bodies.

There is a minimal trade-off in the difference of feel between superwash wool and natural untreated wool. Most consumers find this trade-off in the difference in feel acceptable, given the functional benefits of superwash.

Role in Modern Textile and Fashion Trends

CarbOnized wOOl superwash fabric falls smack in the middle of that trend toward natural fibers and techY upgrades. Modern consumers want clothes to be comfortable, last long, easy to take care of, and not sacrifice anything on quality.

That means scalable boosting production with stable quality, which puts the cherry On tOp Of the global supply chain-in-mOdernist apparel development.

Care Recommendations

Although designed for easy care, garments made from carbonised wool superwash fabric benefit from gentle handling. Washing on wool or delicate cycles with mild detergents and avoiding excessive heat helps preserve softness and appearance over time.

Frequently Asked Questions

Yes, the impurity removal and a controlled surface treatment leave it more friendly to sensitive skin than untreated wool.

Does carbonisation damage wool fibers?

Properly managed carbonisation will remove vegetable matter without leaving the wool fiber significantly weakened.

Superwash treatment reduces breathability?

Superwash does not take away the natural properties of breathability and moisture regulation from wool.

Can carbonised wool superwash fabric be worn year-round?

Sure! Depending on the fabric’s weight and how it’s made, it can be good for different seasons.

Conclusion

Carbonised wool superwash fabric is an advanced version of the regular wool fabric. The intense purification process is combined with a modern shrink proof treatment, which results in a type of fabric that matches all contemporary requirements related to quality, performance, and ease.

The carbonized wool superwash fabric cleans softness with strength and resilience for longevity in a balanced way, adding to its easy care,e which makes it much appreciated by knitwear, fashion, as well as general clothing users. As long as textile innovation continues to pursue the line of functional natural fibers, carbonized wool superwash fabric can be considered both pragmatic and progressive within the global textile industry.