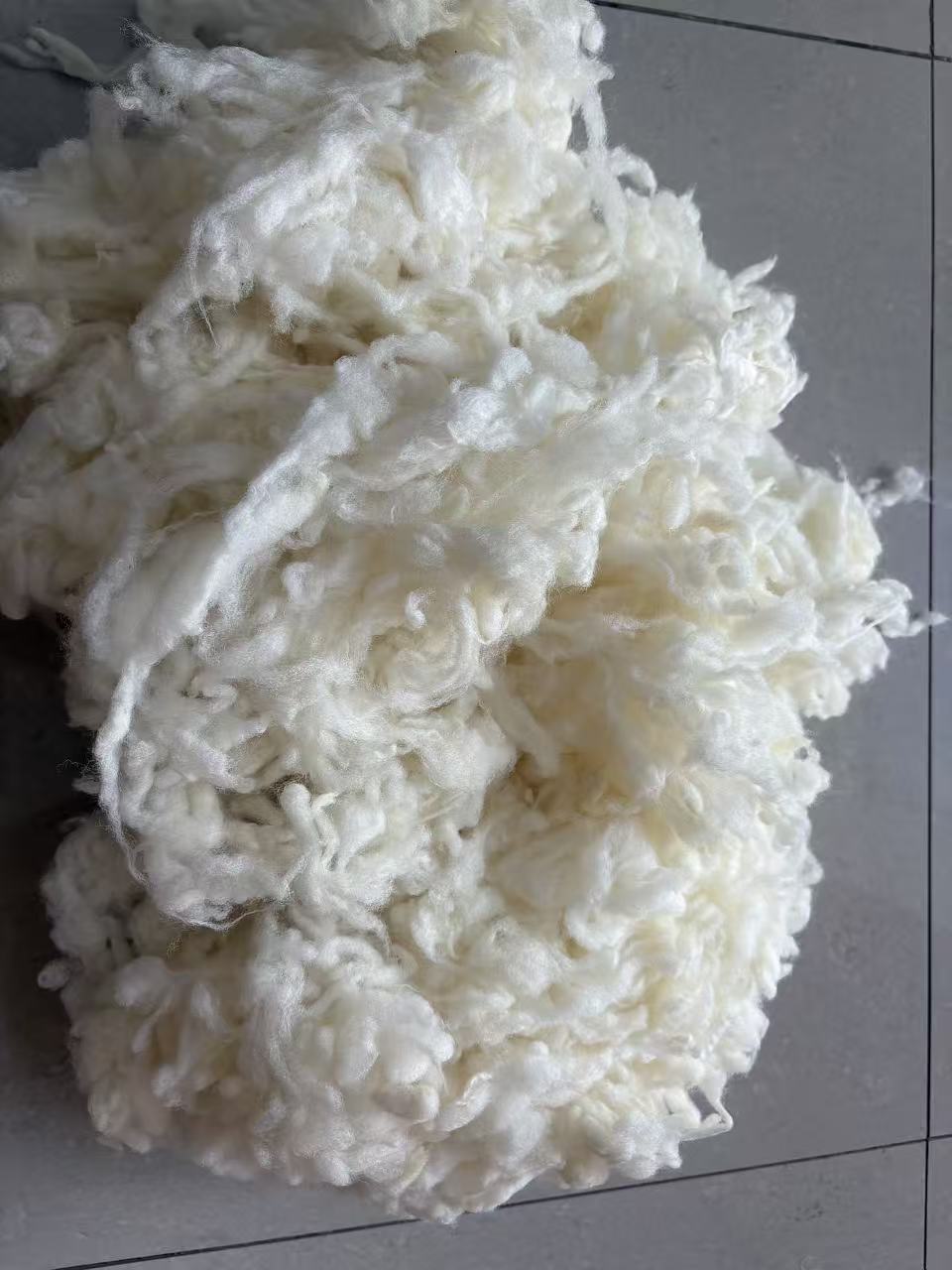

When wool is sheared from sheep, it not only contains fibers, but also contains a variety of other substances: seeds, burrs, grasses, plant stems, and importantly, vegetable matter (VM): soil, dust, and sweat. These impurities, especially plant-based materials, have a significant negative impact on spinning, dyeing, and fabric quality. While standard cleaning (washing) scouring is intended to remove grease, dirt, and soluble impurities, it often fails to eliminate stubborn VMs that are embedded in the fleece. That’s the place where the carbonization process originates: a chemical process that involves mechanical action to eliminate the VM and produce carbonized wool. This is a more refined, higher-quality wool that is ideal for fabric production.

In this article, we discuss the necessity of carbonization, the process’s steps, the necessary parameters, the benefits and risks of the process, and how professionals in the industry should choose when to carbonize wool.

Why Carbonise Wool — The Need for Carbonised Wool

- What issues does vegetable matter (VM) have?

Raw wool (“greasy wool”) typically contains a large amount of VMS: seeds, burrs, grass remnants, twigs, leaf fragments, etc. Some VMs will cause the wool to be unable to be used for fine-fleated or fabric production. If not addressed, the VM can:

Defects in fabric and yarn: obvious spots, uneven coloration, and impurities in the finished product.

Cause problems during processing, including carding, combing, or spinning: burrs and hard seed-heads may lead to the breakage of fibers, machine damage, and increased waste.

Lower the overall quality of fabric, consistency, and appearance, and this will degrade the potential of high-end woollen clothing.

For high-end wool products, especially fine clothing that requires a high degree of purity and uniformity, merely scouring is not sufficient: thorough removal of the virus is necessary.

- Mechanical removal is often not sufficient

In some computer systems (e.g., worsted), combing and carding can take a portion of the VM. However, mechanical processes alone are often ineffective when applied to woollen systems, or when the content in the VM is medium to high. Hard seeds or burrs may be able to survive carding, and a mechanical process can lead to excessive loss of fiber or the breakage of the seed.

As a result, when the content of VM exceeds a certain threshold (typically 2-3%) or includes plant matter that is difficult to remove, such as hard heads of seed or shive, a chemical-mechanical method of removal becomes necessary.

As a result, for many wool-based products, carbonization is still important in order to ensure quality, consistency, and reproducibility.

What is Carbonised Wool — Definition & Scope

Carbonized wool is wool that has been subjected to a chemical process and a mechanical procedure that purges the majority of the vegetable content from the wool. This is done to facilitate conventional cleaning and scouring.

Key points:

Carbonization involves the removal of cellulosic and plant-based pollutants, including cellulose, hemicellulose, and lignin in seeds, stems, and grass. These have a different chemical composition from the wool’s keratin protein.

The procedure utilizes the chemical instability of vegetable materials to deconstruct them into their chemical constituents, while the protein in wool is still more resistant to deconstruction in controlled conditions.

Carbonization is typically employed on stock that is loose and has been scoured in order to be used for woolen spinning. This is uncommon for the worsted method, unless the volume of demand for the product is high.

As a result, carbonized wool is considered an “amended and enhanced” intermediate that is essential to producing superior yarns and fabrics that are free of derived plant specks.

The Carbonisation Process — Step-by-Step Workflow

The common process of carbonization (in many wool manufacturing plants) is composed of several distinct stages. While different variations are possible, the core procedure remains the same.

- Pre-treatment: Scouring ( cleaning of greasy wool)

Before carbonization, wool must first be cleansed – this involves the removal of grease (lanolin), salts, dirt, dust, and water-soluble components. This guarantees that the subsequent acid treatment will directly target the VM instead of interacting with residual grease or other contaminants unpredictably.

In the process of scouring, a greasy goat’s wool traverses a series of washing stations (typically with detergent or alkali), it’s then rinsed and finally dried (or tempered with acid). It’s then prepared for treatment with acid.

This stage is of paramount importance: if the scouring is insufficient, the removal of the VM will be incomplete, or the fibre will be damaged; overzealous mechanical handling will lead to the destruction of short fibers or a decrease in yield.

- Acidizing (Involvement with an Acid Solution)

Once they’ve been scoured and dried (or moisture-adapted), the wool is placed in a bath with acid. Historically, this was most commonly done with sulphuric acid, but other types of acid are now being used as well. Typically, this concentration is 5-7% (w/v) at a controlled temperature. Between 20 and 30 degrees Celsius. A small amount of detergent ( Agent Wetting) may be incorporated into the mix to ensure that the acid uniformly permeates into the vegetable substance.

The acid permeates through the cellulosic material, while wool fibers (protein-based) are more resistant than others. The bath is typically long (a few meters), which will allow for a sufficient amount of time to be spent in the bath (e.g., 5-10 minutes) for acid to become embedded in the VM.

Proper acid composition, contact duration, and wetting are essential: insufficient acid or lack of distribution may lead to poor removal; excessive acid or uneven distribution may harm wool.

- Moisture Extraction (Squeezing or Centrifuging) → Drying

After acidizing, the wool must be removed from the acid and dewatered in order to lower the moisture content before baking. Desiccating wool that contains a lot of water (e.g., 60)% poses a risk of hydrolysis and excessive fiber damage when overheated. As a result, procedures like double squeezing or continuous rotation are employed to reduce the moisture level.

Once the moisture content is reduced, the wool is dried at a low temperature (e.g. 60-80 degrees Celsius) to reach a low threshold — a safer state before baking.

- Baking (The thermal carbonization of vegetable matter)

This is the critical step that involves carbonization: the acid-treated, dried wool is heated to a high temperature (typically 95-120 °C, depending on the type of plant and the wool itself). Under these conditions, the acid promotes the disintegration of VM ( cellulose/hemicellulose/lignin), which are then converted into fragile carbonaceous (charred) remnants.

This charred virtual machine is now brittle, rather than fibrous, and can be removed by mechanical means. The baking process’s temperature and duration must be regulated with care: if the temperature is too low, the VM will remain intact; if the temperature is too high, or if the process is too long, the wool proteins will likely hydrolyze or degrade, which will weaken the fiber’s strength.

- Mechanical Destruction (Burr Crushing &dedusting)

After baking, the brittle carbonized material is removed by hand: wool is employed between heavy fluted rollers, which compact and pulverize the remaining charred material. Next, the wool will travel to a unit dedicated to cleaning and drying (e.g. Shaker that rotates, Willey that cleans steps, and a separate device that removes dust-like particles that are carbonized.

Occasionally, the crushing and deusting stages are repeated multiple times in order to ensure that they are completely removed, especially when the volume of VM was high. The proper configuration of rollers and the gentle nature of the mechanical process are crucial to avoiding fiber compaction, disintegration, or loss.

- Neutralization and washing

Because the wool’s wool after being baked is still acidic, the next step is to neutralize the acid, this is typically accomplished with a solution that contains alkali (e.g. Carbon dioxide is typically added to synthetic fibers to increase the pH to a neutral level (around 6-8), this enables the wool to be safe for further processing (dyeing, spinning).

Neutralization is typically followed by rinsing (with water and a small amount of detergent) that removes remaining acid, salts, and dust.

- (Optional) Blotting and Final Drying

If a pale, uniform fabric is desired (particularly for dyed textiles), carbonized fabric can be whitened, this is accomplished by using a chemical like hydrogen peroxide under a controlled pH condition (e.g. pH 5-7 with formic acid) to eliminate remaining color, enhance the whiteness of the fabric, or prepare the fabric for coloring.

Ultimately, the wool is subject to a variety of processes that result in the removal of excess moisture and the storage of smaller fibers.

Critical Process Parameters and Quality Control — Why Carbonisation Is Sensitive

Because carbonization involves the acidification of wool and the resultant heat, the procedure is easily damaging to the wool’s fibers if not carefully planned. Over time, significant research has been dedicated to optimizing each stage in order to balance the removal of effective VM with the least amount of fibre degradation.

Here are the parameters that are critical to precise control:

Acid concentration and uniform wetting: typical 5-7% sulphuric acid; uneven concentration or poor targeting causes the chemical to fail to reach or bind to the fibers, causing them to become carbonized or damaged.

Moisture content before baking: too much moisture can lead to hydrolysis; the optimal amount of dewatering and drying is critical.

The baking temperature and duration must be sufficient to char the VM while still being gentle enough to preserve the wool proteins; these typically have a temperature of 95-120 degrees Celsius.

Mechanical removal (roller/DEDuster) settings: the necessity of strong crushing is sufficient to break the charred VM, but it is also gentle enough to minimize the entrapment of fibers or the breakage of the VM.

Neutralization time: how long it takes to neutralize the acid; un-neutralized acid can degrade wool over time, negatively impact the color of the fabric, or cause unevenness in the color.

The conditions used to bleach (if present): excessive bleaching can adversely affect fibers or lead to them being fragile; these must be cautiously balanced.

Quality control often includes tests such as alkali solubility (to assess fibre damage), pH measurement, residual cellulose content, and tensile strength/fibre strength — to ensure processed wool remains acceptable for downstream spinning and fabric manufacture.

Because carbonized wool is more porous than scoured wool and has lost the non-protein VM that characterizes it, its capacity to take in dyes may be altered — typically, this is accompanied by an improvement in the acid treatment, but uneven treatment can lead to “spot” or “speck”.

Taking these sensitivities into account, carbonization must be conducted with precise oversight, experienced operators, and after the treatment is complete, the benefits must be realized without negatively impacting the wool’s integrity.

Benefits of Carbonised Wool — Why Industry Still Uses It

Despite its complexity and the loss of carbonizing plants in some areas, carbonized wool still plays a significant role in the production of superior-quality wool and fabric. Key benefits include:

Remove the majority of the vegetable content—seeds, burrs, grasses, shives— from the wool to produce a more refined and superior fabric.

Enhanced fabric and yarn quality – fewer streaks, more uniform coloring, softer surface, more aesthetic, and enhanced performance.

Reduced flaws, less machine damage— during carding, spinning, weaving; fewer breaks associated with burrs, less waste, increased efficiency of processing.

Increased dye retention and uniformity – As a result, carbonized wool is typically more susceptible to dyes, which results in a greater degree of consistency, vividness, and uniform coloration.

Increased value and compatibility with premium fabrics – this is ideal for creating beautiful, detailed patterns that are appropriate for all types of fabric, including worsted and flocked materials, as well as high-end textiles that require purity and consistency.

For fabric mills and textile producers that intend to reach the top end of the wool fabric market, carbonized wool continues to be a significant raw material, enabling products that possess high standards of design, performance, and customer satisfaction.

Risks, Drawbacks & Why Carbonization Has Declined in Some Regions

Carbonization is beneficial, but also carries an implicit risk and a potential trade-off. Eventually, many wool processors in regions with low VM in local sheep cut have abandoned or reduced the practice of carbonizing the wool because of the negative consequences that this has on the local population. Concerned aspects:

- Fiber Breakage and Reduced Density

Acid hydrolysis, especially in the presence of suboptimal conditions (low acid concentration, uneven wetting, high moisture, or improper baking), can lead to the hydrolysis of the peptide bond, chain cutting, and reduced tensile strength.

This deterioration can be expressed as:

Lower strength of yarn and higher probability of breakage during processing.

Reduced garment longevity and resilience — this is a significant downside if the result is a need for long-lasting, strong textiles.

- Loss of weight and yield reduction

The composition of vegetable matter is variable, but it is sometimes significant in the weight of raw wool. When this is removed via carbonization, the total yield of wool is reduced. Additionally, some short or weak wool fibers may be wasted during processing (mechanical compaction or clearing), which further diminishes the yield.

For those who focused on maximizing yield and minimizing waste, this can negatively impact the carbonized wool market, specifically at the beginning of the industry.

- Environmental and Chemical Concerns

Carbonization typically employs sulphuric acid as the acidic medium and produces acidic drainage plus charred plant debris as a byproduct. If the acid is not properly balanced, the treated effluent and dust can pose environmental risks.

Additionally, harsh neutralization, rinsing, and bleaching may utilize chemicals and water, which increases the cost of processing, the volume of wastewater, and the environmental impact.

Because of this concern, some areas (e.g., parts of Europe) have experienced a decline in the number of plants that are carbonizing or the closure of the plant.

- Price, complexity, and throughput limitations

Compared to simple cleaning and mechanical scouring, carbonization is more intricate, time-consuming, and requires precise procedure control, chemical handling, neutralization, and treatment of waste.

Typical production rates are typically low (e.g., 500-600 kilograms of wool per hour for a standard 1800 mm-wide line) – slower than other wool processing methods.

As a result, the expense per kilogram of carbonized wool (versus scoured-only wool) is greater, and the economic viability of the process is dependent on the quality and value of the downstream product.

When to Use Carbonised Wool — Industry Guidelines & Decision Criteria

Taking into account the benefits and trade-offs, deciding if to carbonize wool should be based on specific criteria regarding the raw material’s content of VM, the intended purpose, quality, and economic/ environmental considerations. This is a professional’s guide to the industry:

- Carbonization is Suggested When:

The content of the VM is typically moderate to high (e.g., 2–3%, especially with hard seed heads, burrs, and shive) — mechanical cleaning is unlikely to be effective.

Wool is intended for woollen-spun fabric, high-end clothing, fine jewelry, and apparel that is uniform, pure, consistent in color, and looks good.

Downstream expectations include hygienic, speck-free fabric, even color retention, minimal flaws, and consistent feel.

Advantageous to pay for the cost of taking a risk and receiving a superior return, e.g. high-end textile market.

- Avoid or minimize carbonization when:

The VM’s content is limited (e.g., < 2%), and mechanical processing (carding or combing) is adequate – the cost and risk of damage to the fibers may be more significant than the benefits.

Yarn/ fabric is intended for low-end, rough, woollen goods that have a less stringent aesthetic requirement or color uniformity.

Economic or environmental limitations: for example small-scale producer who has limited chemical treatment capabilities, has a hard time dealing with waste, or when minimizing chemical burden is of paramount importance.

End-use focuses on maximizing the strength of the fiber and its durability, for example. Heavier woolens, solid outerwear, and the risk of acid-induced fiber deterioration are undesirable.

Recent Trends & Alternatives — Industry Evolution and Environmental Considerations

While traditional acid-based carbonization has been common for decades, environmental regulations, cost concerns, and sustainability issues have led to an increase in interest in alternative methods of VM removal.

Several significant advances:

Enzymatic therapy: this involves the use of cellulases, ligninases, or other enzymes that are specific to degrade plant-based materials, avoiding strong acids, decreasing the toxicity of effluents, and possibly enhancing the strength of wool.

Small-scale / closed-loop processing: taking more effective measures to neutralize effluents, treat water, and reuse it to reduce the environmental impact.

Only selective carbonization for high-VM lots: a more stringent distinction between greasy wool and its counterparts to avoid unnecessary carbonization when the VM is already low — this improves the yield and reduces the chemical consumption.

These trends are attributed to the larger pressure within the industry: to maintain quality while also making sure the economic and environmental benefits are balanced with sustainability and responsibility.

What “Carbonised Wool” Means for Buyers, Brands, and Supply-Chain Stakeholders

For brands, manufacturers, or retailers that deal with wool fabric or yarn, understanding how to identify carbonized wool has a practical effect:

Expectations: Carbonized wool has a more hygienic, more uniform fabric, which is important for superior garments or high-end textiles.

consistency and defect reduction: lower concentrations of specks/plant material lead to fewer customer complaints, less fabric rejection, and a positive reputation.

The cost of carbonization is typically higher than the value of the product, but the increased quality often justifies premium pricing, especially in the luxury or fine-wool markets.

Supply chain transparency and sustainability: As environmental concerns increase, it is important to know whether or not wool was acid-carbonized, if any effluent was treated, or if it was treated via a more environmentally friendly method. This information helps to assess the sustainability of the product.

Product description and communication: For B2B or B2C contexts, stating “carbonized wool” (or having only Mechanical Cleaning) can influence the expectations of quality regarding fabric, durability, and dyes; this can reduce returns or dissatisfaction.

As a result, for companies that source or produce wool fabric, carbonization is not considered a simple technical endeavor—but it often has a significant impact on the final product design and the long-term value of the product.

Conclusion — Carbonised Wool: What It Is, Why It Matters, and When to Use It

Carbonized wool is not simply “washed wool” — it is also wool that has undergone additional, chemical-based processing to eliminate embedded plant-based pollutants (vegetable matter) that have a resistance to normal cleaning and scouring. Through a carefully planned sequence — including scouring, acid treatment, dewatering, baking, crushing, and possibly bleaching — carbonization produces wool that is more hygienic, more uniform, and more appropriate for fine spinning, coloring, and superior fabric production.

However, the procedure has associated costs: potential harm to the fibers, decreased yield, environmental and chemical costs, and increased complexity of processing.

For fabric manufacturers, branded fabric, or retailers, the decision to utilize carbonized wool—or specifically describe it— should be based on a balanced evaluation of the raw material’s content of VM, the final product’s requirements (quality, appearance, coloring, performance), cost and sustainability, as well as a balanced assessment of the fabric’s sustainability.

Ultimately, carbonization is still considered a significant, but deliberate, component of the wool processing toolbox. When employed correctly, it allows for the conversion of raw, polluted fleece into quality wool that is suitable for superior fabric. However, it is essential to have precise control, have technical knowledge, and understand the long-term effects of your actions.