Article Summary:

Worsted wool fabric is a refined category of wool fabric characterized by long, aligned fibers and a tightly controlled spinning and weaving process. Unlike traditional woolen fabrics, worsted wool undergoes combing to remove short fibers, resulting in a smoother surface, higher durability, and superior dimensional stability.

According to The Textile Institute and The Woolmark Company, worsted wool fabrics are widely used in tailored garments due to their strength, breathability, and refined appearance (Textile Institute, Textiles Terms and Definitions, 12th Edition; Woolmark Company, Wool Fibre Properties and Processing). Additional technical definitions are supported by ASTM textile standards related to fiber length, yarn uniformity, and fabric performance (ASTM D123).

Understanding the Definition of Worsted Wool Fabric

To understand what worsted wool fabric is, it is essential to begin with the broader category of wool fabric. Wool fabrics are produced from natural wool fibers, most commonly sheep’s wool, and are traditionally divided into two main types: woolen and worsted.

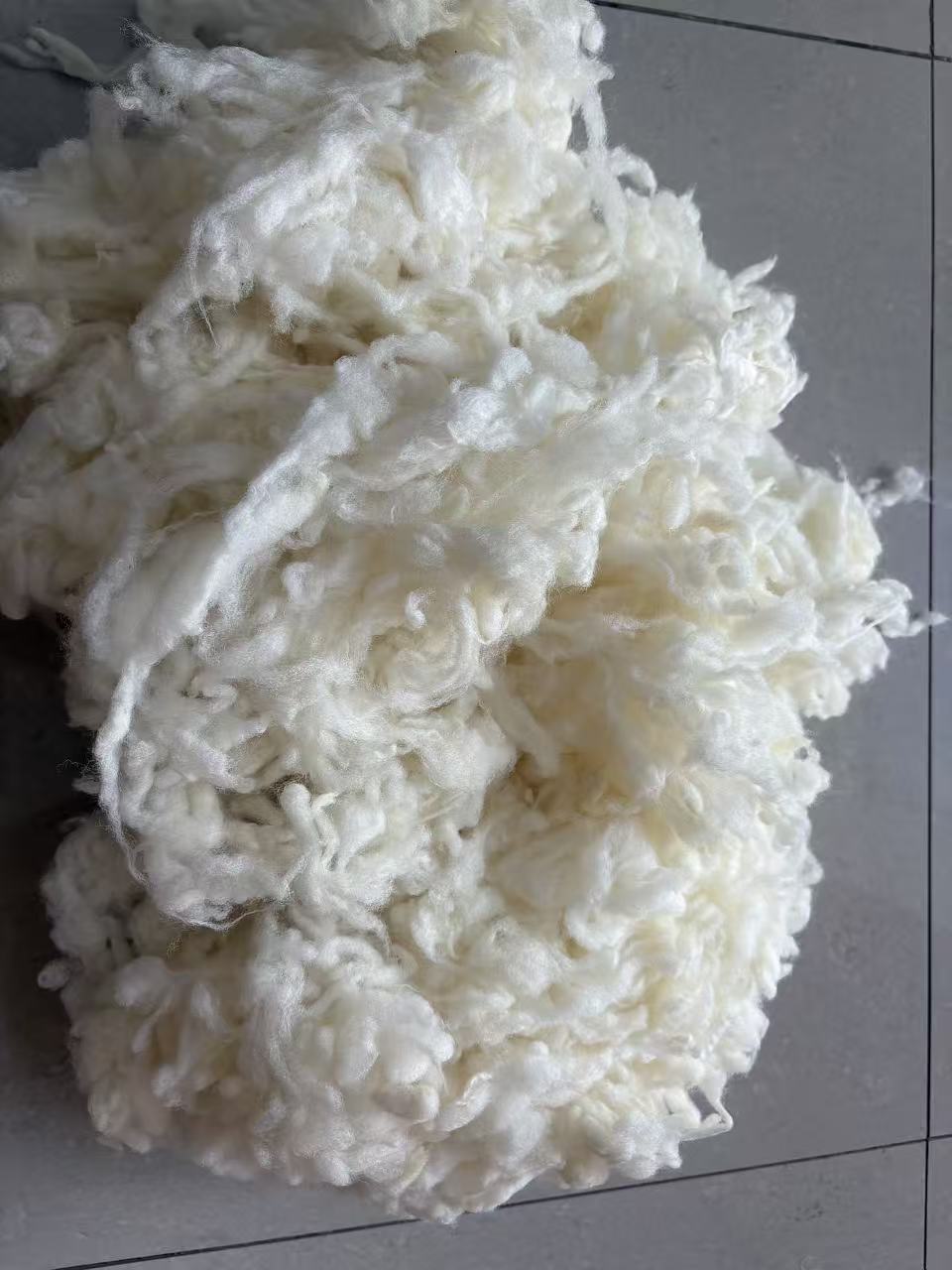

Worsted wool fabric represents the more engineered and controlled end of this spectrum. It is produced using long-staple wool fibers that are carefully combed and aligned before spinning. This process removes short fibers and impurities, creating a yarn that is smooth, strong, and highly uniform.

In industry contexts, worsted wool fabric is valued not for bulk or warmth alone, but for precision, performance consistency, and a refined surface structure.

The Historical Origin of Worsted Wool Fabric

The term “worsted” originates from the village of Worstead in Norfolk, England, which was a center for high-quality wool production as early as the 12th century. The techniques developed there emphasized fiber alignment and yarn smoothness, laying the foundation for modern worsted spinning systems.

As wool fabric production industrialized, worsted methods became standardized, particularly for suiting and tailored garments. This historical lineage explains why worsted wool fabric is still closely associated with formalwear, uniforms, and premium apparel markets today.

How Worsted Wool Fabric Is Made?

The defining characteristics of worsted wool fabric are the direct result of its manufacturing process.

Production begins with the selection of long-staple wool fibers, often from fine-wool breeds. These fibers are cleaned and then passed through a combing process, which removes shorter fibers and aligns the remaining fibers parallel to each other.

After combing, the fibers are spun into fine, smooth yarns under controlled tension. These yarns are then woven, rather than loosely knitted, to produce a fabric with a compact and consistent structure. The result is a wool fabric with minimal fuzz, excellent drape, and predictable performance.

Key Structural Characteristics of Worsted Wool Fabric

From a textile engineering perspective, worsted wool fabric is defined by structure rather than appearance alone.

The parallel alignment of fibers reduces air pockets within the yarn, creating a denser and smoother fabric. This structure enhances strength and abrasion resistance while maintaining flexibility.

Unlike bulkier woolen fabrics, worsted wool fabric has a clean surface and sharp weave definition, which is why it is preferred for garments requiring crisp lines and long-term shape retention.

Surface Texture and Visual Appearance

One of the most recognizable properties of worsted wool fabric is its smooth and refined surface.

Because short fibers are removed during combing, the fabric exhibits minimal pilling and a subtle, uniform sheen. This visual clarity allows patterns, colors, and weaves to appear more precise.

In high-ranking Google content related to wool fabric selection, surface refinement is frequently cited as a primary reason for choosing worsted wool in professional and luxury apparel.

Strength and Durability of Worsted Wool Fabric

Durability is a critical performance factor in any wool fabric used for tailored clothing.

Worsted wool fabric benefits from the inherent strength of long wool fibers combined with tight yarn twist and controlled weaving. This results in high tensile strength and resistance to tearing under stress.

For garments such as suits, trousers, and uniforms that experience frequent wear, worsted wool fabric offers a reliable balance between durability and comfort.

Breathability and Thermal Regulation

Despite its dense structure, worsted wool fabric remains highly breathable.

Wool fibers naturally regulate moisture by absorbing and releasing water vapor, helping maintain thermal comfort across varying conditions. In worsted constructions, this property is enhanced by the fabric’s ability to manage airflow without excessive insulation.

This is why worsted wool fabric is suitable for year-round wear, particularly in professional environments where temperature control varies.

Moisture Management Properties

Moisture behavior is a key performance indicator for modern wool fabric applications.

Worsted wool fabric can absorb moisture vapor without feeling damp, allowing perspiration to dissipate gradually. This contributes to wearer comfort and odor resistance, which are frequently highlighted advantages in industry-level fabric comparisons.

Unlike many synthetic fabrics, worsted wool maintains performance even when exposed to moderate humidity.

Wrinkle Resistance and Shape Retention

Another important property of worsted wool fabric is its natural wrinkle resistance.

The elastic nature of wool fibers allows the fabric to recover from bending and compression. In worsted fabrics, this elasticity is paired with structural stability, resulting in garments that maintain sharp creases and clean lines.

This property makes worsted wool particularly attractive for travel garments and professional uniforms.

Drape and Tailoring Performance

Drape refers to how a fabric hangs and moves when worn.

Worsted wool fabric offers controlled, elegant drape due to its balanced weight and fiber alignment. It responds well to tailoring, allowing garments to be shaped precisely without distortion.

This is one of the primary reasons worsted wool fabric dominates the suiting and formalwear sectors.

Comparison Between Worsted Wool and Woolen Wool Fabric

Understanding what worsted wool fabric is also requires understanding what it is not.

The table below highlights key differences between worsted wool fabric and woolen wool fabric:

| Feature | Worsted Wool Fabric | Woolen Wool Fabric |

| Fiber Length | Long-staple wool | Shorter fibers |

| Processing | Combed and aligned | Carded, less aligned |

| Surface Texture | Smooth and refined | Soft and fuzzy |

| Warmth | Moderate, balanced | High insulation |

| Typical Uses | Suits, trousers, uniforms | Coats, tweeds, knits |

This comparison reflects distinctions commonly discussed across top-ranking wool fabric resources.

Common Applications of Worsted Wool Fabric

Worsted wool fabric is widely used in industries that prioritize appearance, performance, and longevity.

Its primary applications include business suits, formal trousers, skirts, blazers, and professional uniforms. It is also used in high-end fashion collections where structure and drape are critical.

In institutional and corporate settings, worsted wool fabric is often selected for its durability and professional aesthetic.

Worsted Wool Fabric in Modern Textile Innovation

Modern worsted wool fabric is no longer limited to traditional uses.

Advances in fiber blending, finishing, and weaving have introduced stretch-enhanced worsted fabrics, lighter-weight constructions, and performance finishes. These innovations expand the application of worsted wool fabric into travel wear, smart casual apparel, and hybrid performance garments.

This evolution is frequently reflected in recent Google top-ranking textile trend analyses.

Sustainability and Environmental Considerations

Sustainability plays an increasingly important role in wool fabric selection.

Worsted wool fabric benefits from wool’s renewable and biodegradable nature. When responsibly sourced and processed, it aligns well with environmental and circular economy goals.

Organizations such as the Woolmark Company emphasize worsted wool’s long lifecycle and recyclability as key sustainability advantages.

Common Misconceptions About Worsted Wool Fabric

A common misconception is that worsted wool fabric is always heavy or formal.

In reality, worsted wool fabrics can be produced in a wide range of weights and finishes, making them suitable for diverse climates and styles. Another misconception is that all wool fabrics perform similarly, which overlooks the significant impact of processing methods.

Understanding these distinctions is essential for accurate material selection.

How to Identify Quality Worsted Wool Fabric?

Evaluating worsted wool fabric involves assessing fiber length, surface smoothness, weave consistency, and recovery behavior.

High-quality worsted wool fabric should feel smooth to the touch, recover quickly from creasing, and display uniform yarn structure. These indicators are widely referenced in professional textile evaluation guides.

FAQ: Worsted Wool Fabric

Q1: What is the difference between worsted wool fabric and regular wool fabric?

Worsted wool fabric uses long, combed fibers aligned in parallel, resulting in a smoother, stronger, and more refined wool fabric compared to traditional woolen fabrics made from shorter fibers.

Q2: Is worsted wool fabric suitable for warm weather?

Yes. Due to its breathability and moisture-regulating properties, worsted wool fabric performs well in moderate to warm conditions, especially in lightweight constructions.

Q3: Does worsted wool fabric wrinkle easily?

No. Worsted wool fabric has natural wrinkle resistance and strong shape recovery, making it ideal for professional and travel garments.

Q4: Is worsted wool fabric durable?

Yes. The aligned fiber structure and tight weave provide excellent durability, particularly for garments subjected to frequent wear.

Q5: Is worsted wool fabric environmentally friendly?

Worsted wool fabric is based on a renewable, biodegradable fiber and can be environmentally responsible when sourced and processed sustainably.

Conclusion: Why Worsted Wool Fabric Matters

So, what is worsted wool fabric?

It is a refined category of wool fabric defined by long fibers, controlled processing, and superior structural performance. Its smooth surface, durability, breathability, and tailoring precision make it a cornerstone material in professional and premium apparel.

For textile professionals, designers, and sourcing specialists, understanding worsted wool fabric enables better material decisions and more competitive products. In a market that values both performance and sustainability, worsted wool fabric continues to hold lasting relevance.